Project Overview

案例概述

Mengniu's yogurt Division has established a water circular economy system centered on efficient water resource recycling. Addressing the high water consumption inherent in dairy production, the division leverages digital and intelligent technologies alongside full-chain management optimization to implement a “monitoring-optimization-recycling-coordination” framework.

Specific actions are as follows:

(1) Deploying smart metering devices covering 99% of water usage points to enable real-time data collection and visual management of water consumption;

(2) Developing a digital CIP cleaning algorithm that reduced ineffective cleaning rates from 38% to 24%, minimizing water waste during cleaning processes;

(3) Establishing a three-tier reuse system (“production water – recycled water – reclaimed water”), achieving a 95% reuse rate for cooling water and daily reclaimed water reuse of 600 tons per factory;

(4) Promoting cross-departmental collaboration to integrate water data with carbon management and ESG systems, forming a systematic water conservation mechanism.

Ultimately, these initiatives resulted in a 15% reduction in water consumption per ton of product, increased water resource recycling rates to 35%, and earned four factories national “Green Factory” certification. The Tai'an factory achieved AWS (The Alliance for Water Sustainability) Gold Level certification, providing replicable best practices for water recycling in the dairy industry.

蒙牛低温事业部以水资源高效循环利用为核心,结合乳制品生产高耗水特点,通过数智化技术应用与全链条管理优化,构建了“监测-优化-循环-协同”的水循环经济体系。

具体行动包括:

(一)部署智能计量设备覆盖99%用水点,实现水耗数据实时采集与可视化管理;

(二)开发数字CIP清洗算法,将无效清洗率从38%降至24%,减少清洗环节水资源浪费;

(三)建立“生产用水—循环水—中水”三级回用体系,冷却用水回用率达95%,单厂日中水回用量600吨;

(四)跨部门协同推动水数据与碳管理、ESG体系融合,形成系统化节水机制。

最终经实践后,单吨产品水耗下降15%,水资源循环利用率提升至35%,4家工厂获国家级“绿色工厂”认证,泰安工厂通过AWS(国际可持续水管理联盟)黄金级认证,为乳制品行业水循环利用提供了可复制的实践经验。

Company/Organization Profile

机构简介

Mengniu High-Tech Dairy Products (Beijing) Co., Ltd. was established on February 14, 2014. As a high-tech enterprise under Mengniu Dairy Group, it specializes in the research, development, and production of low-temperature fermented milk and lactic acid bacteria beverages. Located in the Food Industrial Park of Lucheng Town, Tongzhou District, Beijing, the company operates 11 production lines with a daily capacity of 411 tons. Its products are distributed across 17 provinces and municipalities nationwide. Possessing proprietary bacterial strains that have achieved industrial-scale application, the company demonstrates outstanding technological capabilities. Concurrently, it places high priority on environmental protection, having invested over 20 million yuan in wastewater treatment to ensure compliant discharge. With a registered capital of 87.5 million yuan, all capital has been fully paid in.

蒙牛高科乳制品(北京)有限责任公司成立于2014年2月14日,是蒙牛乳业集团旗下专注于低温发酵乳及乳酸菌饮料研发与生产的高新技术企业。公司位于北京市通州区潞城镇食品工业园区,拥有11条生产线,日产能达411吨,产品覆盖全国17个省市。具备自主知识产权菌株并实现工业化应用,技术实力突出。同时,公司高度重视环保,累计投入超2000万元用于污水处理,确保达标排放。注册资本8750万元,已全部实缴。

Project Outcome

项目成果

1. Water conservation and emission reduction: In 2024, the entire business division will save 300,000 tons of water (including 120,000 tons of wastewater reuse) and reduce wastewater discharge by 120,000 tons, with significant achievements in water-scarce northern regions.

2. Cost optimization: Annual savings in water fees, energy consumption and maintenance costs amount to 9 million yuan. Four factories have been awarded the "Green Factory" certification, enjoying tax benefits of 2 million yuan.

3. Ecological benefits: The annual COD load on water bodies has been reduced by 50 tons, groundwater extraction has been decreased, and the low-temperature dairy products have been certified as "Green Products", with a 1.5% increase in market share.

4. Industry leadership: A white paper on water conservation management was released, and participation in the formulation of industry water circulation standards was carried out. The exhibition hall has popularized water conservation knowledge to 5,000 people annually.

5. Chain-driven development: 30 suppliers were trained, driving upstream water savings of 50,000 tons annually. A green supply chain was constructed, forming a "large enterprise leading" model.

1. 节水减排:2024年全事业部节水30万吨(含12万吨废水回用),减少废水排放12万吨,北方缺水地区成效显著。

2. 成本优化:年节约水费、能耗及维修成本900万元,4家工厂获“绿色工厂”认证享税收优惠200万元。

3. 生态效益:降低水体COD负荷50吨/年,减少地下水开采,助力低温乳制品通过“绿色产品”认证,市场份额提升1.5%。

4. 行业引领:发布节水管理白皮书,参与制定行业水循环标准,开放展厅年普及节水知识5000人次。

5. 链动发展:培训30家供应商,带动上游年节水5万吨,构建绿色供应链,形成“大企业引领”模式。

Project Highlights

项目亮点

Mengniu Dairy has established a water circulation system featuring “graded reuse and digital management,” achieving annual water savings of 50,000 tons. The company's factory earned AWS Gold Level certification and participated in setting industry standards. Its water conservation education exhibition hall welcomed 5,000 visitors during its open year, driving the green transformation of 30 suppliers and creating replicable industry solutions. As China's sole dairy enterprise, it was honored with the 2024 International Quality for Sustainable Development Award.

蒙牛乳业构建"分质回用+数字管理"水循环体系,年节水5万吨,工厂获AWS黄金级认证并参与制定行业标准。开放年接待5000人次节水教育展厅,带动30家供应商绿色转型,形成可复制的行业解决方案。作为中国唯一乳企荣获2024年国际质量促可持续发展奖。

Project Implementation

项目实施

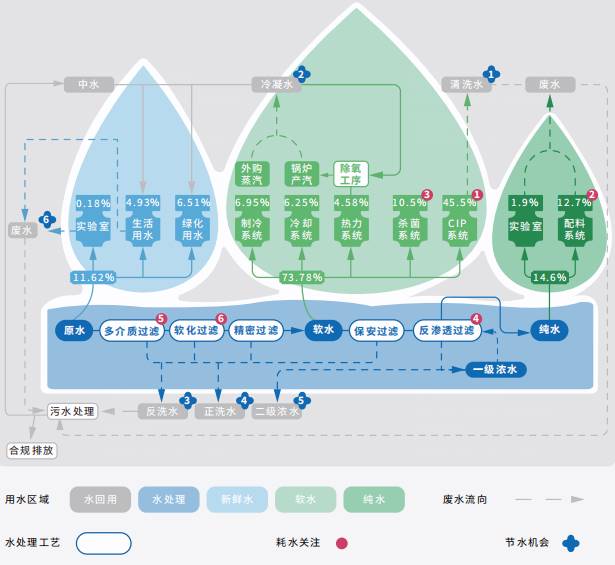

Mengniu Dairy's Yogurt Division has established a digital water conservation management system through a four-dimensional closed-loop model of “monitoring-optimization-reuse-collaboration,” enabling precise control over the entire water resource lifecycle. By deploying a smart metering network covering 99% of water usage points—integrating smart water meters, flow meters, and water quality sensors—the division leverages industrial IoT for sub-second data collection and anomaly alerts. This boosts response efficiency by 95% (from 48 hours to 1 hour) while generating real-time reports analyzing water consumption distribution across processes (e.g., 42% for cleaning, 28% for cooling), providing data-driven insights for water conservation decisions. An innovative water footprint visualization tool dynamically displays the factory's water usage flowchart, precisely labeling water consumption, quality changes, and discharge paths at each stage to form a closed-loop visual management system.

蒙牛低温事业部以"监测-优化-回用-协同"四维一体的闭环管理模式,构建数字化节水管理体系,实现水资源全生命周期精准管控。通过部署覆盖99%用水点的智能计量网络,集成智能水表、流量计与水质传感器,依托工业物联网实现用水数据秒级采集与异常预警,响应效率提升95%(从48小时缩短至1小时),同步生成各环节用水占比分析报表(清洗占42%、冷却占28%),为节水决策提供数据支撑。创新开发水足迹可视化工具,动态呈现工厂用水流程图,精准标注各环节用水量、水质变化及排放路径,形成可视化管理闭环。

In process optimization, the pioneering application of digital CIP cleaning technology employs intelligent algorithms to monitor product residue in real time and automatically optimize cleaning parameters. This enables dynamic water temperature adjustment (80°C → 60°C) and precise flow control. Combined with a program verification module to eliminate equipment idling, the Meishan plant reduced ineffective cleaning time by 73%, achieving annual water savings of 12,000 tons. Simultaneously advancing quality-based treatment and reuse technologies, cooling water undergoes sand filtration + activated carbon filtration for reuse in floor washing. The Beijing plant achieves a 95% reuse rate, saving 300 tons of water daily. Washing wastewater treated with membrane filtration technology is reused in condensers. The Qingyuan plant averages 15 tons of reclaimed water reuse daily, significantly enhancing water resource utilization.

在工艺优化方面,率先应用数字CIP清洗技术,通过智能算法实时监测产品残留量并自动优化清洗参数,实现水温动态调节(80℃→60℃)、流量精准控制,配合程序校验模块消除设备空转,使眉山工厂无效清洗时间降低73%,年节水1.2万吨。同步推进分质处理与回用技术,冷却用水经砂滤+活性炭过滤后回用于地面冲洗,北京工厂实现95%回用率,日节水300吨;清洗废水采用膜过滤技术处理后回用于冷凝器,清远工厂日均中水回用15吨,显著提升水资源利用率。

We innovatively introduced the 3U water conservation strategy (Use Less, Use Again, Use Together), mapped the entire plant's water flow, categorized water usage units by area/category/consumption, systematically identified 23 water-saving opportunities, and established a full-process management mechanism covering water extraction, usage, treatment, and reuse. A cross-departmental coordination system was formed, with specialized task forces comprising production, equipment, environmental protection, and quality control. This created a “data-driven - process optimization - standard assurance” linkage mechanism: production departments provide real-time feedback on process requirements; environmental protection departments strictly monitor recycled water quality compliance (meeting the “Urban Wastewater Reuse Standards”); and quality control departments verify key indicators such as microbiological parameters to ensure recycled water safety. Simultaneously, the Water Recycling Management Specifications were developed, incorporating per-ton product water consumption and reclaimed water reuse rates into departmental KPIs. Standardized operating procedures and quantitative evaluation metrics were established.

创新提出3U节水策略(节约使用Use Less、循环使用Use Again、共同使用Use Together),绘制全厂水流向地图,按区域/类别/耗量划分用水单元,系统识别23个节水机会点,建立覆盖取水、使用、处理、回用的全流程管理机制。构建跨部门协同体系,由生产、设备、环保、品控组建专项工作组,形成"数据驱动-工艺优化-标准保障"的联动机制:生产部门实时反馈工艺需求,环保部门严格监测回用水质达标(符合《城市污水再生利用标准》),品控部门验证微生物等关键指标,确保回用水安全。同步制定《水循环利用管理规范》,将单吨产品水耗、中水回用率纳入部门KPI考核体系,建立标准化操作流程和量化评价指标。

Following implementation, Mengniu's YogurtDivision achieved intelligent water monitoring, precision process optimization, systematic resource reuse, and standardized collaborative management, establishing a replicable water conservation model. Through dual-engine digitalization and technological innovation, annual water savings are projected to reach 200,000 tons, reducing water consumption per unit of product by 18%, setting a benchmark for green transformation in the food industry.

该项目实施后,蒙牛低温事业部实现用水监测智能化、工艺优化精准化、资源回用系统化、协同管理标准化,形成可复制的节水管理范式。通过数字化手段与技术创新双轮驱动,预计年度节水总量可达20万吨,单位产品水耗下降18%,为食品行业绿色转型提供标杆案例。

Project Impact & Sustainability

项目影响力、可推广性与可持续性

Mengniu's Yogurt Division has established a new paradigm for water resource management in the food industry through its innovative “quality-based reuse + digital management” model. This approach leverages deep process integration as a technical breakthrough, enabling data-driven water control and standardized construction of recycling systems. It has earned AWS Gold Level certification and industry-wide recognition. Post-implementation, the project conserves 50,000 tons of water annually, alleviating regional water supply pressure while creating a replicable “technical-economic-ecological” synergistic solution: internally rolled out to ambient temperature and milk powder divisions; externally driving 2,000 tons/year water savings across upstream/downstream operations like dairy farms, generating 15,000 yuan in economic value. By establishing a full-chain water circular economy system, the project not only addresses the high water consumption challenge in the food industry but also creates a sustainable development mechanism of “standard output + benefit sharing.” It provides a demonstrably viable model for the dairy industry's green transformation, combining both technical feasibility and commercial viability. Future efforts will focus on continuously optimizing the intelligent monitoring system and driving the establishment of industry standards.

蒙牛低温事业部通过"分质回用+数字管理"创新模式,构建了食品行业水资源管理新范式。该模式以工艺深度耦合为技术突破点,实现用水数据化管控与循环系统标准化建设,获AWS黄金级认证及行业权威认可。项目实施后年节水5万吨,降低区域供水压力的同时,形成可复制的"技术-经济-生态"协同解决方案:内部已向常温、奶粉事业部推广;外部带动牧场等上下游节水2000吨/年,创造1.5万元经济价值。通过建立全链条水循环经济体系,项目不仅破解了食品行业高耗水难题,更形成"标准输出+效益共享"的可持续发展机制,为乳制品行业绿色转型提供了兼具技术可行性与商业可行性的示范样本,后续将持续优化智能监测系统并推动行业标准制定。

(Using AI translation)

(使用AI翻译)

零废弃学校建设之厨余垃圾篇

10-24 · 来源:中国浙江省宁波市鄞州第二实验中学 · 作者:中国浙江省宁波市鄞州第二实验中学

能源至净,生活至美,积极打造碳中和

10-24 · 来源:中国石化销售股份有限公司海南海口石油分公司 · 作者:中国石化销售股份有限公司海南海口石油分公司

无锡中瑞低碳生态城

10-23 · 来源:无锡中瑞低碳生态城 · 作者:无锡中瑞低碳生态城