In March 2022, the National Development and Reform Commission and the National Energy Administration jointly issued the Medium and Long-term Plan for the Development of Hydrogen Energy Industry (2021-2035), which made it clear that hydrogen energy is an important part of the future national energy system.

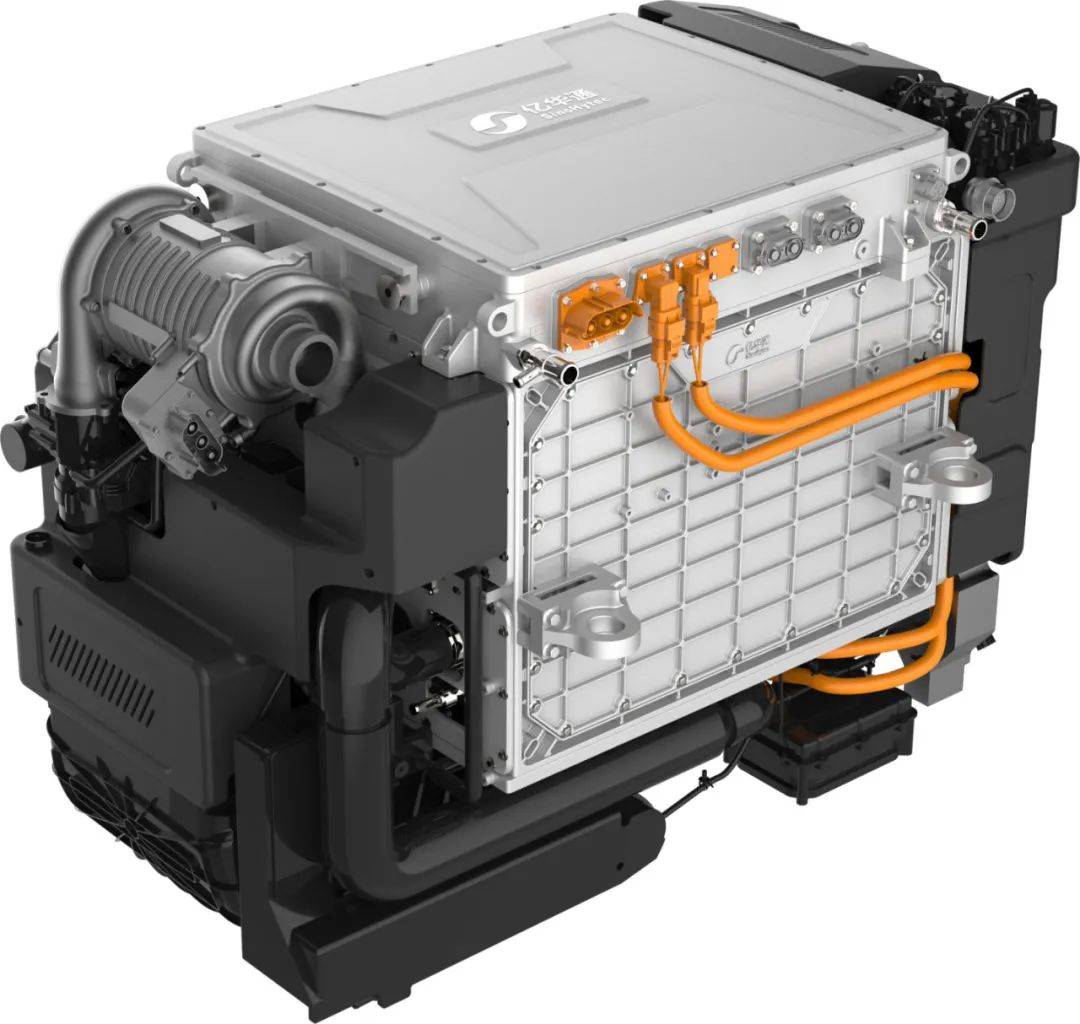

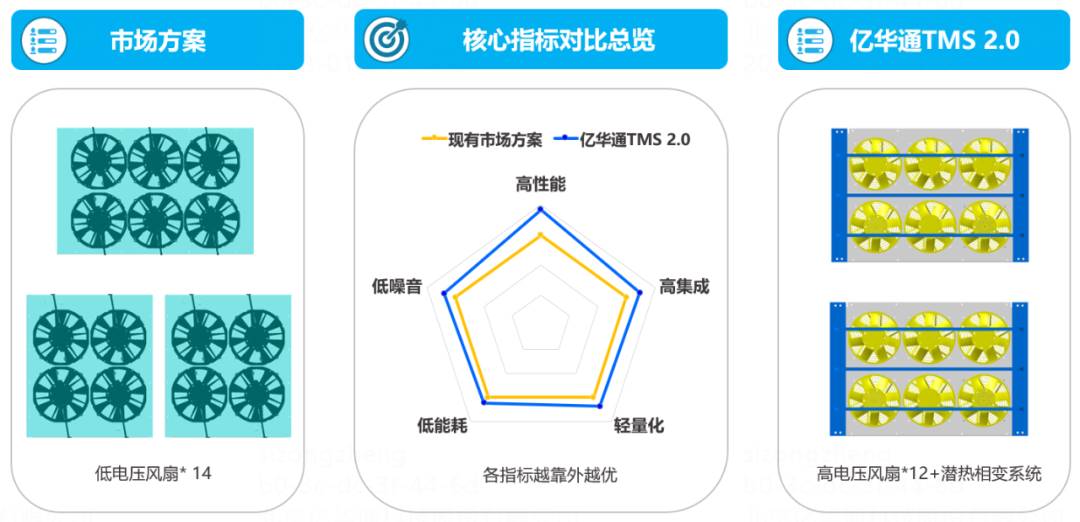

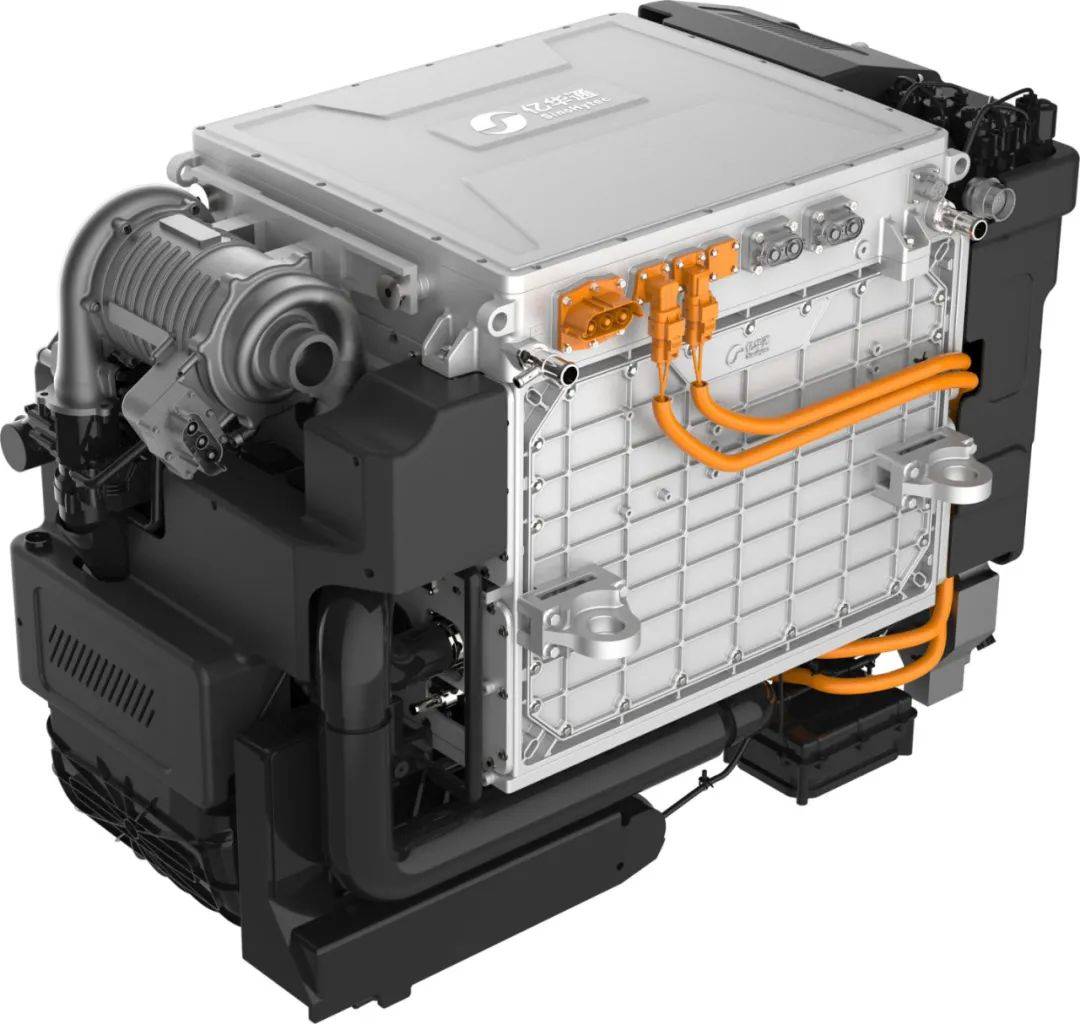

In order to solve this industry problem and promote the batch application of high-power fuel cell engines, Sinohytec has carried out a lot of forward-looking technology exploration and research, and developed a high-power fuel cell thermal management system TMS 2.0 for heavy trucks based on its strong R&D strength. Compared with the mainstream thermal management solutions in the current market, Sinohytec TMS 2.0 thermal management system has the technical advantages of high performance, high integration, lightweight, low energy consumption and low noise.

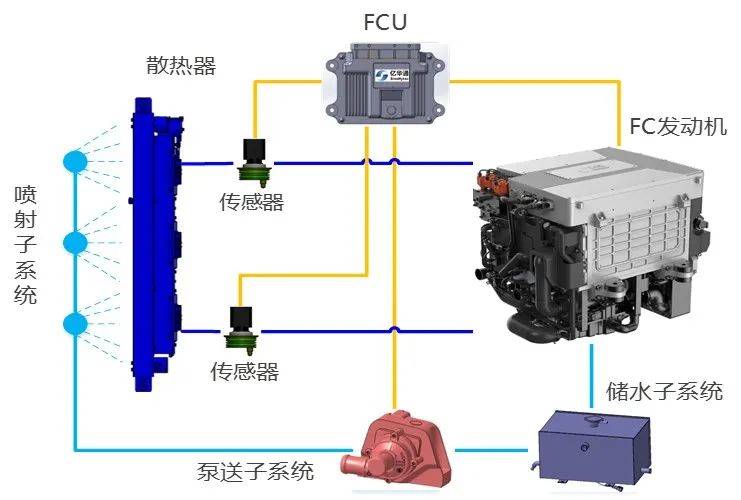

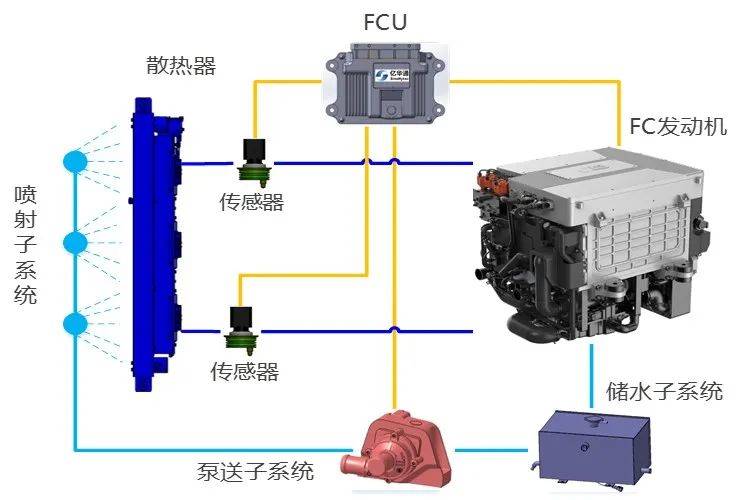

Sinohytec latent heat of vaporization system ingeniously uses the self-produced water of fuel cell as the cooling medium of latent heat of vaporization, quickly responds to the heat dissipation demand of the engine, sprays water evenly on the outer surface of the radiator, and uses the phase change of water vaporization to take away the heat generated by the stack. The system mainly comprises a water storage subsystem, a pumping subsystem and an injection subsystem, and adopts closed-loop control to accurately control the injection amount as required. At the same time, the subsystem components are generalized and can be quickly adapted to different engine platforms.

Sinohytec has cooperated with domestic advantageous suppliers to develop a "high voltage platform + DC brushless" cooling fan with independent intellectual property rights, which has a wide working voltage range of 400-750V and a wide dynamic speed range of 500-4700RPM, realizing low power consumption and low noise, canceling the distribution device of high voltage to low voltage, and improving the cooling fan. The cost is saved and the overall efficiency of the system is improved.

TMS 2.0 can meet the cooling requirements of fuel cell engines with rated power of 200-360 kW.

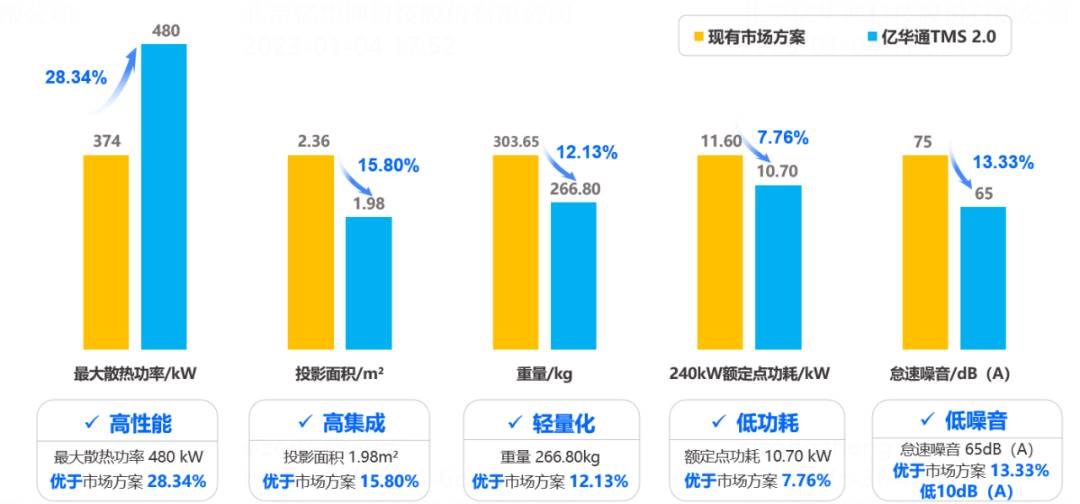

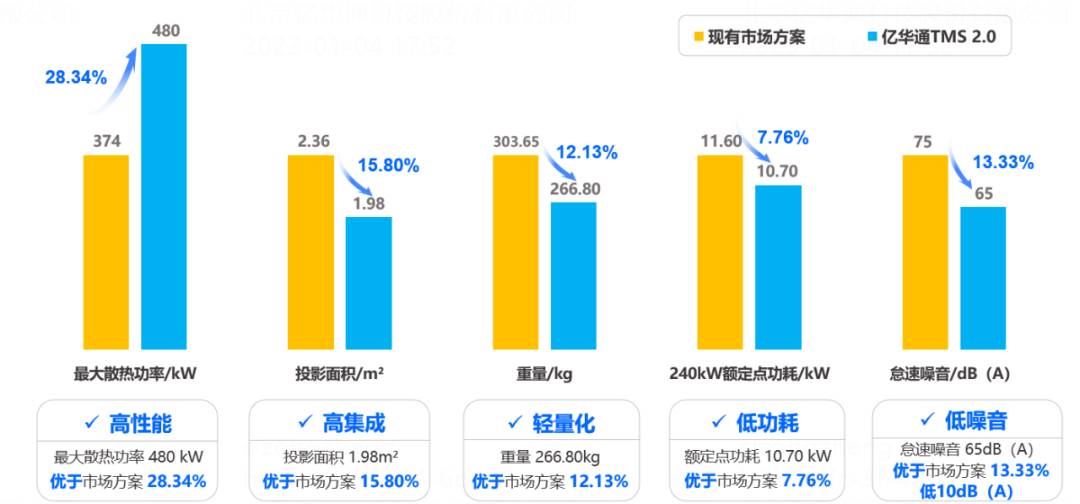

Benefiting from the excellent performance of the high-pressure fan, the excellent heat dissipation capacity of the latent heat of vaporization, and the iterative improvement results of multi-round simulation analysis of the radiator core, the maximum heat dissipation power of TMS 2.0 thermal management system reaches 480 kW, which is 28.34% better than that of the market scheme.

Through the modularization of latent heat of vaporization and the miniaturization design of the heat dissipation system, the TMS 2.0 thermal management system is highly integrated, with a projection area of only 1.98 m², which is 15.80% better than the market solution.

The traditional means of improving the heat dissipation performance, such as increasing the number of fans and increasing the radiator core, are not adopted, the heat dissipation technology of latent heat of vaporization phase change is innovatively utilized, and the performance of the latent heat system is brought into full play through multiple rounds of accurate simulation and adjustment, so that the parasitic power consumption of the thermal management system is significantly reduced. When the engine power is 240kW, the power consumption of TMS 2.0 thermal management system is 7. 76% better than that of the market scheme.

By accurately optimizing the number of blades and parameters of the high-pressure fan and the aerodynamic characteristics of the fan, the low noise of the TMS 2.0 system is realized, and the idle noise is 65dB (A), which is 13.33% better than that of the market scheme and 10 dB (A) lower.

As of December 2022, In the field of

thermal management, Sinohytec has applied for 120 technical patents such as

"a Multi-stack Fuel Cell Thermal Management System", "a

Calibration Method for Fuel Cell Thermal Management System", "a Fuel

Cell Heat Management System for Heavy Trucks", "A System for Increasing

the Heat Dissipation Capacity of Fuel Cells" and "a Hysteresis

Compensation Control Method for Fuel Cell Heat Management Systems".

As a leading enterprise in the field of hydrogen energy in China, Sinohytec has always adhered to its mission, taking advanced hydrogen fuel cell technology as the breakthrough point, contributing to China's goal of "carbon peaking, carbon neutrality", promoting the global energy revolution, striving to become the leader of global hydrogen fuel cell technology, and building a sustainable low-carbon future. In order to promote the rapid development of the fuel cell heavy truck industry, the company decided to take the initiative to disclose relevant thermal management technology patents, share relevant technology research results with global industry partners, promote the rapid development of the hydrogen energy industry, and contribute to the bright future of the earth.

2022年3月,国家发改委和能源局联合发布了《氢能产业发展中长期规划(2021-2035 年)》,明确了氢能是未来国家能源体系的重要组成部分。

我国重卡保有量超过1000万辆,占汽车总量的2.6%,但碳排放占47%。一辆49吨柴油重卡的二氧化碳排放量约等于40辆小轿车的排放量 。因此,重卡减碳迫在眉睫。搭载燃料电池是重卡减碳的主要路径。重型卡车具有载重大、车速高、续驶里程长的特点,氢燃料电池能量密度高,氢燃料电池重卡具有续驶里程长、低温环境适应性好、0碳排放等优势。目前搭载氢燃料电池发动机的重卡越来越多、应用场景越来越丰富。但是,重卡搭载的燃料电池发动机额定功率高达240kW,这对热管理系统提出了更严苛的性能需求。

为解决这一行业难题,推动大功率燃料电池发动机批量应用,亿华通开展了大量前瞻性的技术探索与研究,基于强大研发实力开发了重卡专用大功率燃料电池热管理系统TMS 2.0。相比目前市场主流的热管理方案,亿华通TMS 2.0热管理系统具有高性能、高集成、轻量化、低能耗、低噪音的技术优势。

亿华通汽化潜热系统巧妙地利用燃料电池自产水,作为汽化潜热的冷却介质,快速响应发动机的散热需求,将水均匀喷射于散热器外表面上,利用水汽化相变带走电堆产生的热量。系统主要包含储水子系统、泵送子系统、喷射子系统,采用闭环控制,按需精确控制喷射量。同时,子系统部件通用化,可快速适配不同的发动机平台。

亿华通联合国内优势供应商开发了具有自主知识产权的“高电压平台+直流无刷”散热风扇,具有400~750V宽幅工作电压区间、500~4700RPM宽动态转速范围,实现了低功耗、低噪音,取消了高压转低压的配电装置,节约了成本、提升了系统的整体效率。

TMS 2.0可满足额定功率200-360kW燃料电池发动机的散热需求。

受益于高压风扇的优良性能、汽化潜热出色的散热能力,以及散热器芯体多轮仿真分析迭代改进成果,TMS 2.0热管理系统最大散热功率达480kW,优于市场方案28.34%。

通过汽化潜热模块化以及散热系统的小型化设计,TMS 2.0热管理系统集成度高,投影面积仅为1.98m²,优于市场方案15.80%。

不采用增加风扇数量、不增加散热器芯体等传统的散热性能提升手段,创新性地利用汽化潜热相变的散热技术,并通过多轮精确仿真和调校,充分发挥潜热系统的性能,显著降低了热管理系统的寄生功耗。发动机功率240kW时,TMS 2.0热管理系统功耗优于市场方案7.76%。

通过精确优化高压风扇的叶片数量及参数、风扇气动特性,实现了TMS 2.0系统的低噪音,怠速噪音65dB(A)优于市场方案13.33%,低10dB(A)。

截至2022年12月,亿华通热管理领域已申报《一种多电堆燃料电池热管理系统》、《一种燃料电池热管理系统的标定方法》、《一种用于重卡汽车的燃料电池热管理系统》、《一种用于增加燃料电池散热能力的系统》、《一种燃料电池热管理系统的迟滞补偿控制方法》等技术专利120项。

作为中国氢能领域的领军企业,亿华通始终坚守使命,以先进的氢燃料电池技术为切入点,为中国“碳达峰、碳中和”目标作出贡献,推进全球能源革命,致力成为全球氢燃料电池技术的引领者,构建可持续的低碳未来。为了推动燃料电池重卡行业快速发展,经公司研究决定,亿华通主动公开相关热管理技术专利,与全球行业伙伴共同分享相关技术研究成果,促进氢能行业的快速发展,为地球的美好未来贡献力量。

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报