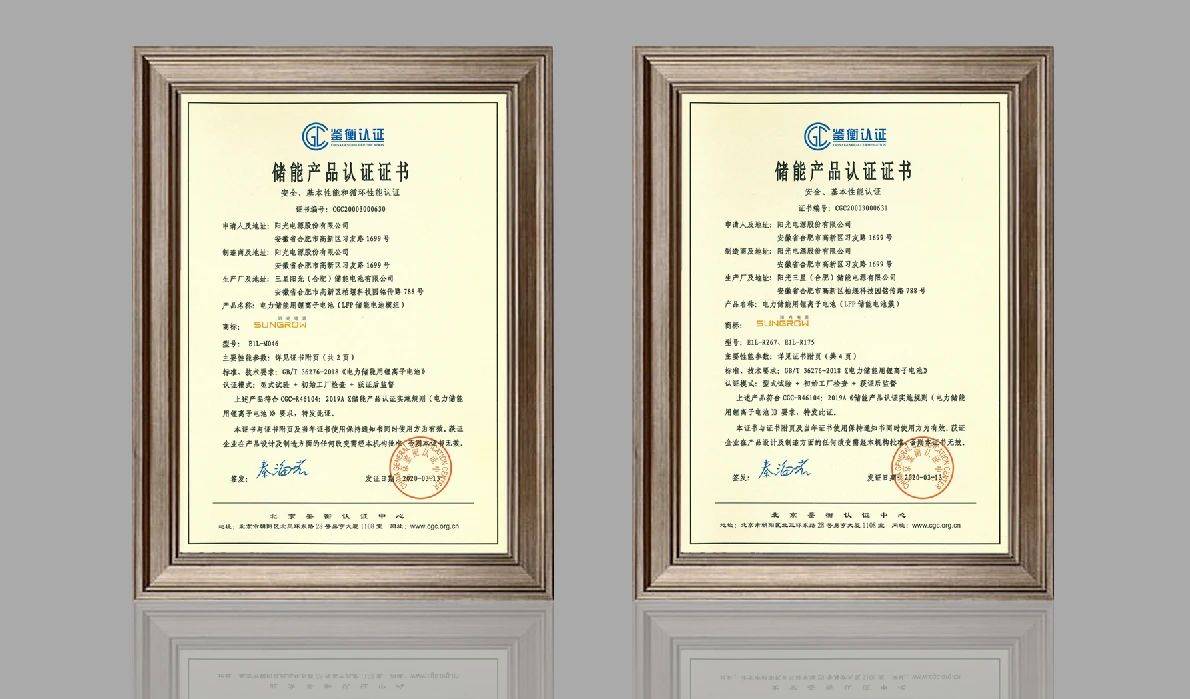

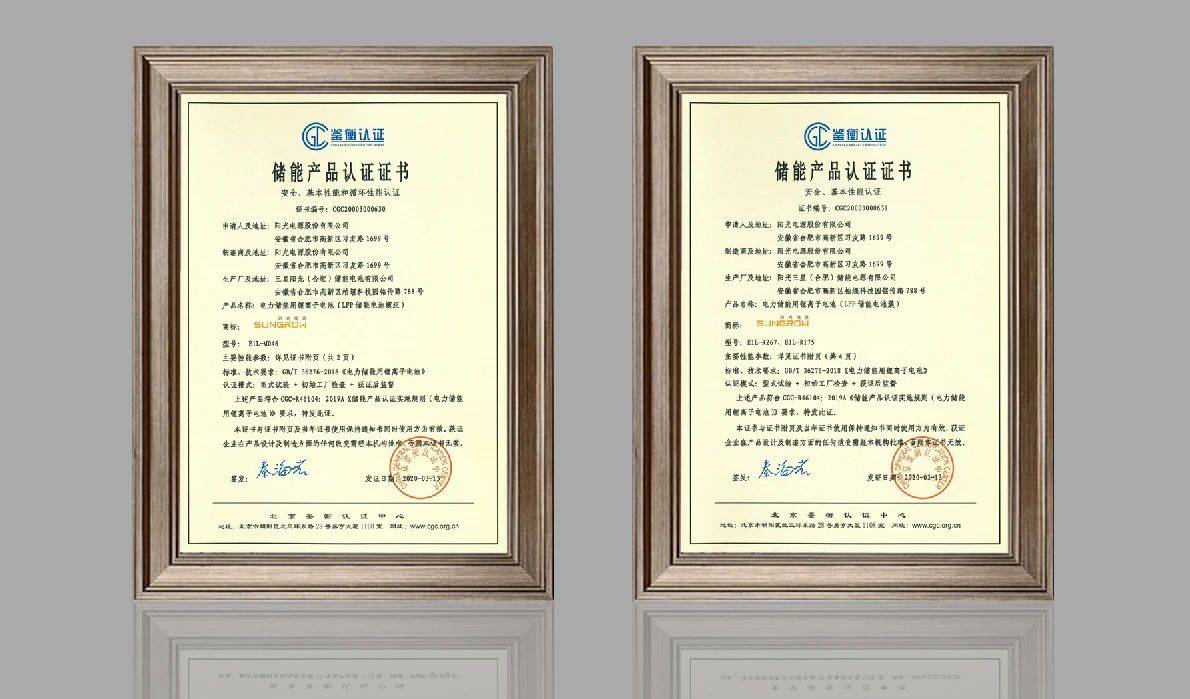

Recently, Sungrow Power has obtained the national standard certification certificate of lithium-ion battery modules and cluster products for electric energy storage issued by the authentication and verification, becoming the first enterprise to complete the trinity certification from battery monomer, module to battery cluster.

National

standard issued

Energy storage by Sungrow Power is fully certified

In 2019, "GB/T 36276-2018 Lithium ion Battery for Electric Energy Storage", the first national recommended standard for lithium battery application in the electric power field, was published. Compared with international standards, it has finer and more comprehensive requirements on battery performance and thermal runaway indexes, which plays a higher guiding role in the development of energy storage technology.

According to the national standard requirements, only get the battery certification of the enterprise can get the subsequent module and battery cluster certification, the whole process enterprises need to go through a lot of rigorous experiments to obtain a full range of certification. Among them, only the type test is as many as 40 items, including thermal runaway, thermal diffusion, cycle performance 500 times of charge and discharge, constant power charge and discharge control and other harsh tests, can develop in a short time to meet the national standard products manufacturers are not many.

In addition, this technological upgrade around the standard must overcome the safety and efficiency of two major difficulties. Sunshine power energy storage system integration products, the director of the center report is introduced, since the national standard implementation, sun power at the early stage of the summary based on rich experience in product development and testing certification, quickly organized a team, according to the national standard of various conditions, optimize the iron lithium battery energy storage system research and development, and finally successfully completed the certification.

Based on the single iron lithium battery, it can meet the application of DC1500V energy storage system. The SOC accuracy is better than 3%, and the temperature difference between batteries is lower than 3℃..... A series of product test details and data fully demonstrate the efforts of Sunbeam Power in the past year, but also marks the arrival of the era of iron lithium energy storage system standardization.

Technical

support for industrialization

900+ major projects around the world 0 safety accidents

As

the integrator of energy storage system, Sun Power has done a lot of research

on the safety design, thermal management, fire protection and protection

coordination of battery system. Years of technology accumulation and continuous

R&D investment in energy storage system integration are strong guarantees

to successfully pass this certification test.

Evaluation scale electronic electrical and energy storage, head of the line customer Zhang Guangqing think: standard type test and on the basis of complete certification implementation rules there is obvious difference to the requirement of the enterprise, certification in addition to type testing the samples, also for factory production certification product ability, quality assurance ability, to evaluate the ability of mass production to ensure product consistency. In particular, Sunshine Power can take the lead in developing products according to national standards, and complete production line layout, adjustment, operation and maintenance, which reflects the solid technical reserves of technical staff for many years and the industrial technical strength of the enterprise.

At present, SunPower has participated in more than 900 major energy storage projects around the world, without a single safety accident, and has won the trust and support of many customers. Energy storage as the key to the development of new energy in the future, its system must take into account security and economy. In the future, Sunshine Power will continue to adhere to the concept of safety, reliability and efficiency, adhere to strict control of the safety design from battery to system, fully ensure the reliability of energy storage system, and provide the world's first-class integrated energy storage system solutions for the new energy industry.

近日,阳光电源获得了由鉴衡认证颁发的电力储能用锂离子电池模组和簇级产品国标认证证书,成为国内第一家完成从电池单体、模组到电池簇三位一体认证的企业。

国标颁布

阳光电源储能获全方位认证

2019年,备受关注的锂电池在电力领域应用的首个国家推荐性标准——《GB/T 36276-2018 电力储能用锂离子电池》问世,与国际标准相比,其在电池性能和热失控指标方面要求更细、更全面,对储能技术的发展起到了更高水平的引导作用。

按照国标要求,只有拿到电池单体认证的企业才能拿到后续的模组和电池簇认证,整个过程企业需要经过大量严苛的实验才能获得全方位认证。 其中仅型式试验的测试就多达40多项,包括热失控、热扩散、循环性能500次充放电、恒功率充放电控制等多项严酷测试,能在短时间开发出符合国标产品的厂家并不多。

此外,围绕标准的这场技术升级,必须攻克安全和效率两大难关。 阳光电源储能系统集成产品中心总监李国宏介绍,自国标实施以来,阳光电源在总结前期丰富的产品研发和测试认证经验基础上,快速组织了一支团队,依据国标各项细则,对铁锂电池储能系统研发方面进行优化,最终顺利地完成了此次认证。

基于铁锂电池单体,满足DC1500V储能系统应用,SOC精度优于3%、电池之间温差低于3℃.....一连串的产品测试细节和数据充分证明了阳光电源在过去1年里投入的心血,也标志着铁锂储能系统的标准化时代已经到来。

产业化技术实力支撑

全球900+重大项目0安全事故

作为储能系统集成商,阳光电源针对电池系统的安全性设计、热管理、消防及保护协调等方面做了大量的研究。 多年的技术积累和在储能系统集成方面持续研发投入是顺利通过这一认证测试的有力保障。

鉴衡电子电气及储能客户线负责人张光青认为: 标准型式试验检测与依据实施规则完成认证对于企业的要求是有明显区别的,认证除了对样品进行型式试验外,还对厂家批量生产认证产品的能力、质量保证能力、确保批量生产产品一致性的能力进行评估。 尤其是阳光电源能够率先依据国标开发产品、并完成产线布局、调整、运维,这体现了技术人员多年的扎实技术储备以及企业产业化技术实力。

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报