The transportation industry is an important area of carbon emission reduction, of which road transportation accounts for 74% of the total carbon emissions of the transportation industry. It is noteworthy that commercial vehicles are the key and difficult areas of carbon emission reduction in the transportation industry. As the leader of new energy vehicles in China, BYD has accelerated technological innovation and actively participated in market practice in the field of new energy commercial vehicle manufacturing in recent years to help the development of new energy commercial vehicle industry. However, the future breakthrough of key technologies for commercial vehicles still faces multiple opportunities and challenges.

一、Background and status of commercial vehicle electrification

Commercial vehicles are a key and difficult area for carbon emission reduction in the transportation industry. 2021, China's overall commercial vehicle sales of 4.79 million units, accounting for only 19% of total vehicle sales, but contributed 65% of total vehicle carbon emissions. Among them, trucks are the major emitters of pollutants and the main source of greenhouse gases in the transportation sector due to their many operating scenarios, complex working conditions and high energy consumption.

1. The current situation of China's new energy commercial vehicle market

Driven by the "dual carbon" goal, the research and development and promotion of new energy commercial vehicles have accelerated, and the market penetration rate of new energy commercial vehicles has increased year by year. In January-August 2022, the sales of new energy commercial vehicles reached 163,000 units, a significant increase compared with last year, despite the continuous low sales of vehicles nationwide. Among them, in the sales of new energy commercial vehicles in the first half of the year, the switch to heavy trucks was an eye-catching performance, with sales reaching nearly 6,000 units. At present, China's urban bus has basically realized electrification (electrification rate of 99%), but the penetration rate of new energy vehicles in other commercial fields such as road passenger transportation, urban logistics, sanitation operations, building flow, etc. is still relatively low.

2. Challenges to the development of new energy commercial vehicles

Under the "three vertical and three horizontal" R&D layout of the "New Energy Industry Development Plan (2021-2035)" issued by the State Council, enterprises are carrying out R&D of new energy and energy-saving vehicles for commercial vehicles around different technical lines for different scenarios, with multiple heads and flowers blossoming.

However, at this stage, the promotion of new energy commercial vehicles, especially medium and heavy-duty new energy commercial vehicles, still need to overcome the range, charging speed, weather resistance and other technical problems, but also face the lack of construction of charging infrastructure, high acquisition costs, some technical standards are not uniform and other challenges.

二、BYD Commercial Vehicle Technology Innovation and Market Practice

1. BYD Commercial Vehicle Development History

BYD started the research and development of lithium iron phosphate (LFP battery) before entering the automotive industry. After entering the automotive industry, it mainly engaged in the R&D of pure electric city buses in the early stage, and started the R&D of pure electric trucks after 2012.

As early as 2015, BYD released its "7+4" market-wide strategic layout for new energy vehicles, covering seven conventional and four special areas of the automotive industry. Under the guidance of the company's strategy, BYD Commercial Vehicle further explores the new energy commercial vehicle market in eight fields, including urban bus, long-distance passenger transportation, sanitation, commodity logistics, building flow, storage, port, airport and mining.

2. BYD Commercial Vehicle Technology Innovation

Driven by the twin wheels of "design and technology", BYD has set up several R&D centers to carry out global commercial vehicle R&D, and built several world-class laboratories for commercial vehicles and core components to provide comprehensive protection for product performance.

BYD insists on technological innovation and independent research and development, independent research and development of core products and technologies related to commercial vehicles, development of industry-leading high-safety power batteries, high-performance integrated drive bridges, all-in-one electronic control with high-efficiency IGBTs, and other products.

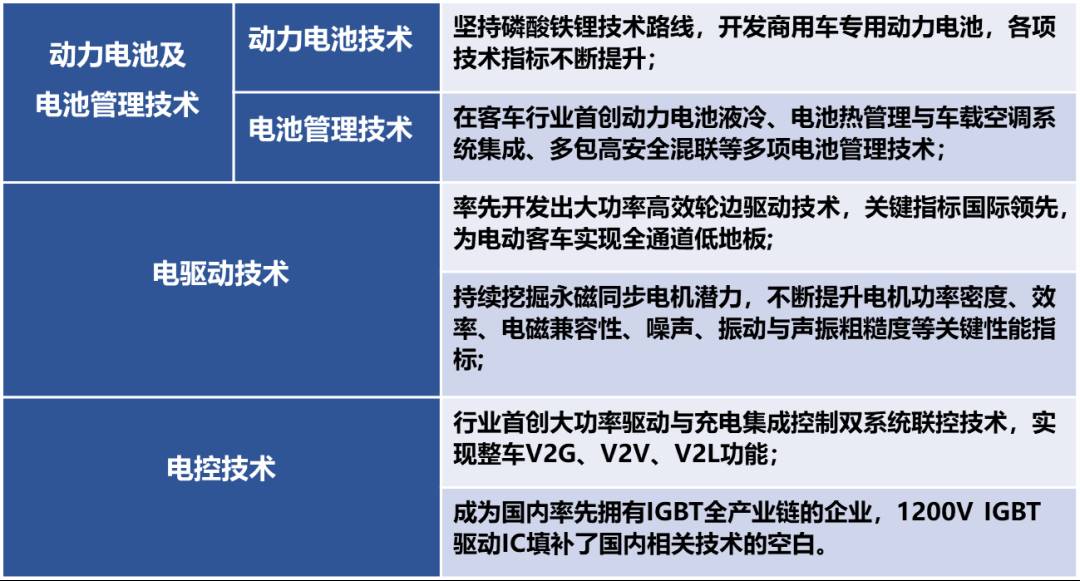

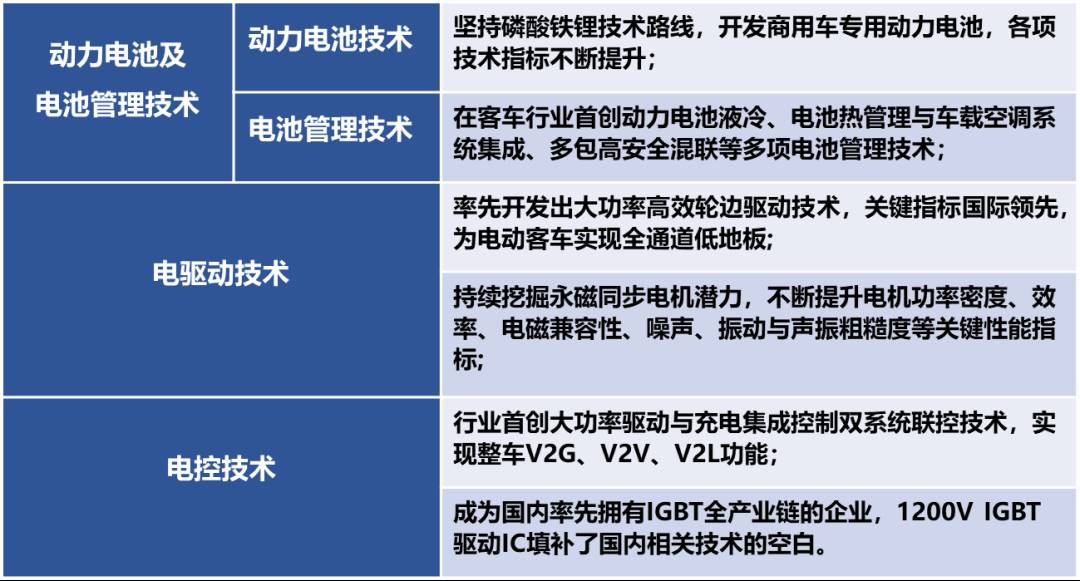

Table 1: BYD's technological innovation achievements in battery, electric drive and electric

3. Innovation results and market performance

Relying on its leading core technology and strong vehicle R&D capability, BYD has developed a full range of products for commercial vehicle application scenarios, and has achieved good results in both domestic and international markets. Up to now, BYD's new energy commercial vehicles have fully entered developed markets in Europe, the United States, Japan and Korea, covering 6 continents, more than 50 countries and regions, and more than 300 cities around the world, with a total of more than 90,000 vehicles, more than 10 billion kilometers of operation, and a total CO2 emission reduction of 7 million tons.

三、The key technology development trend of commercial vehicles

Power Battery and Management Technology

Commercial vehicle power battery development faces unique challenges, the safety performance of the battery should be matched with the commercial vehicle use scenario, need to take into account the cycle life improvement and the use of scenario-specific special design. In the future, BYD will adhere to lithium iron phosphate as the correct technical route for power batteries, while further improving the product's energy density and space utilization and other performance.

In terms of battery management, there will be a breakthrough in efficient cooling and heating technology in the future to further improve the environmental adaptability and efficiency of the battery, etc.

Motor electric control technology

Motor electric control technology will develop towards integration, high efficiency and high reliability.

Integration: Based on the integration of motor electric control and motor drive bridge, integration of BMS and other control systems to form an integrated drive system with deep integration to improve drive efficiency and reduce energy consumption.

High efficiency: With the use of high voltage platforms and silicon carbide semiconductor chip applications, drive efficiency will be further improved in the future.

High reliability: We ensure the high reliability of commercial vehicles in terms of maintenance-free design, failure mode analysis of products, verification algorithm of products, and functional safety.

Complete Vehicle Technology

Lightweighting: In the future, new structures, materials and processes for lightweighting will be developed through new material research, structural optimization and integrated design, and new process research.

Energy saving and consumption reduction: optimize wind resistance coefficient and roll resistance coefficient, develop dynamic energy management technology.

Thermal management technology: energy coupling of motor electric control, power battery and thermal management of member cabin to realize efficient thermal management of the whole vehicle; development of wide temperature range and large displacement heat pump air conditioner.

Intelligent Technology

According to the characteristics of different operation scenarios, intelligent driving technology is gradually being implemented in various application areas. Among them, semi-enclosed scenes such as ports, airports, mines and steel mills are suitable for smart driving landing, while users have strong demand for lower operating costs and have taken the lead in realizing smart driving operation.

The integration of intelligent and networked development is the main theme of the development of new energy vehicles, and has made important breakthroughs in environmental awareness, intelligent decision-making, information interaction and roadside infrastructure. In the future, intelligent networked vehicles will also be integrated with smart cities and smart transportation, and the integrated development of "vehicle-road-cloud" can significantly reduce the number of traffic accidents, significantly improve traffic efficiency, reduce road transport energy consumption, and help "double carbon" goals as early as possible. This will help to achieve the goal of "double carbon" as soon as possible.

In the future, BYD will adhere to independent research and development, continue to carry out technological innovation and practice, and continue to make efforts in the three electric technologies, vehicle technology, intelligent technology, etc., to promote the transformation of commercial vehicle electrification and help achieve carbon neutrality in transportation.

交通运输业是碳减排的重要领域,其中道路运输占交通行业碳排放总量的74%。值得注意的是,商用车更是交通运输行业碳减排的重点及难点领域。比亚迪作为我国新能源汽车的引领者,近年来在新能源商用车制造领域加速开展技术创新、积极参与市场实践,助力新能源商用车行业发展。但是未来商用车关键技术的突破仍面临多重机遇与挑战。

一、商用车电动化背景及现状

商用车是交通行业碳减排重点及难点领域。2021年,我国商用车整体销量479万辆,仅占汽车总销量19%,但贡献了汽车碳排放总量的65%。其中卡车由于作业场景多、工况复杂、能耗高,是交通领域污染物排放大户、温室气体的主要来源。

1. 我国新能源商用车市场现状

“双碳”目标推动下,新能源商用车的研发和推广工作加速发展,新能源商用车市场渗透率逐年提升。2022年1-8月,在全国汽车销量持续走低的情况下,新能源商用车销量低开高走,达到16.3万辆,较去年大幅提升。其中,在上半年新能源商用车的销售中,换电重卡表现抢眼,销量达到近6000台。目前,我国城市公交已基本实现电动化(电动化率达99%),但道路客运、城市物流、环卫作业、建筑物流等其它商用领域新能源车渗透率依然较低。

2. 新能源商用车发展面临挑战

在国务院发布的《新能源产业发展规划(2021-2035年)》“三纵三横”研发布局下,针对不同场景需求,企业围绕不同技术路线开展商用车新能源和节能汽车的研发工作,多头并进、百花齐放。

然而,现阶段新能源商用车的推广,特别是中重型新能源商用车,仍需攻克续驶里程、充电速度、耐候性等技术难题,同时也面临充电基础设施建设不足、购置成本高、部分技术标准不统一等挑战。

二、比亚迪商用车技术创新与市场实践

1. 比亚迪商用车发展历程

比亚迪在进入汽车行业前就启动了磷酸锂铁电池(LFP电池)研发工作。进入汽车行业后,早期主要从事纯电动城市公交研发,2012年后启动了纯电动卡车研发。

早在2015年,比亚迪发布了新能源汽车“7+4”全市场战略布局,覆盖汽车行业7个常规领域和4个特殊领域。在公司战略的指引下,比亚迪商用车进一步探索城市公交、长途客运、环卫、商品物流、建筑物流、仓储、港口、机场、矿山等八个领域新能源商用车市场。

2. 比亚迪商用车技术创新

在“设计和技术”双轮驱动下,比亚迪成立多个研发中心,开展全球化商用车研发,并建成多个国际一流的商用车整车及核心零部件实验室,为产品性能提供全面保障。

比亚迪坚持技术创新和自主研发,商用车相关核心产品和技术自主研发,开发行业领先的高安全动力电池、高性能集成驱动桥、高效率IGBT的多合一电控等产品。

表1. 比亚迪在电池、电驱、电动领域部分技术创新成果

3. 创新成果与市场表现

依托于领先的核心技术和强大的整车研发能力,比亚迪已开发了面向商用车应用场景的全系列产品,并在国内外市场均取得佳绩。截至目前,比亚迪新能源商用车已全面进入欧、美、日、韩等汽车发达市场,足迹遍布全球6大洲、50多个国家和地区、300多个城市,总投放车辆数超过9万台,总运营里程超过100亿公里,总二氧化碳减排量达到700万吨。

三、商用车关键技术发展趋势

动力电池及管理技术

商用车动力电池发展面临特有挑战,电池的安全性能应与商用车使用场景匹配,需兼顾循环寿命提高与使用场景特定的专用设计等。未来,比亚迪将坚持磷酸铁锂作为动力电池正确的技术路线,同时进一步提升产品的能量密度及空间利用率等性能。

在电池管理方面,未来将在高效制冷制热技术上有所突破,进一步提高电池的环境适应性和效率等。

电机电控技术

电机电控技术将朝着集成化、高效率、高可靠发展。

集成化:在电机电控一体化、电机驱动桥一体化设计基础上,融合BMS等控制系统,形成深度集成的集成式驱动系统,提高驱动效率、降低能耗。

高效率:随着高电压平台使用和碳化硅半导体芯片应用,未来驱动效率将进一步提高。

高可靠:从免维护设计、产品的失效模式分析、产品的验证算法、功能安全等方面保证商用车的高可靠性使用需求。

整车技术

轻量化:未来将通过新材料研究、结构优化和集成设计、新工艺研究等,开发轻量化的新结构、新材料、新工艺。

节能降耗:优化风阻系数和滚阻系数、研发动态能量管理技术。

热管理技术:将电机电控、动力电池以及成员舱的热管理进行能量耦合,实现高效的整车热管理;研发宽温域、大排量热泵空调。

智能化技术

依据不同运营场景特点,智能驾驶技术正在各个应用领域逐步落地。其中港口、机场、矿场、钢厂等半封闭场景适合智能驾驶落地,同时用户对降低运行成本需求强烈,已率先实现智能驾驶运营。

智能化与网联化融合发展是新能源汽车发展的主旋律,目前已在环境感知、智能决策、信息交互以及路侧基础设施等方面取得重要突破。未来,智能网联汽车也将和智慧城市、智慧交通融合发展,“车路云”一体化协同发展能够大幅降低交通事故数量,显著提升交通效率,降低道路运输能源消耗,助力“双碳”目标尽早实现。

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报