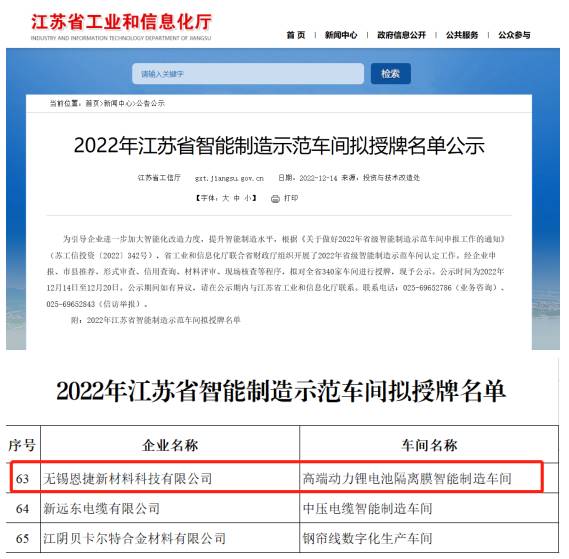

Recently, Jiangsu Provincial Department of Industry and Information Technology together with the provincial Department of Finance organized the identification of the 2022 provincial intelligent manufacturing demonstration workshop, and publicized the 2022 Jiangsu Province intelligent manufacturing demonstration workshop award list, Wuxi Energy New Materials New Materials Technology Co., LTD. "High-end power lithium battery isolation membrane intelligent manufacturing workshop" was selected.

What is a "smart workshop"?

Smart workshop refers to the application of

digital technology and intelligent equipment in the workshop of manufacturing

enterprises, to promote equipment networking and digital connection of

production links, to achieve production data connectivity, manufacturing

flexibility and intelligent management, so as to achieve the effect of cost

reduction, quality improvement and efficiency improvement.

The "Intelligent manufacturing

Demonstration Workshop of Jiangsu Province" should comprehensively examine

the advanced level of equipment in the production system of the enterprise, the

degree of automation of the production process, the precision standard of the

production process and many other factors, and make an authoritative assessment

of the enterprise in accordance with the "Made in China 2025"

standard and the development requirements of intelligent manufacturing.

Wuxi Energy New Materials belongs to Yunnan

Energy New Materials Technology Co., LTD., which is a new energy material

enterprise integrating technology development, manufacturing and sales. Its

products mainly include lithium battery diaphragm and water treatment membrane.

In the construction of intelligent production with virtual server technology as

the core, the implementation of digital transformation.

Wuxi Energy New Materials is affiliated to Yunnan Energy New Materials shares. It is a new energy material enterprise integrating technology development, manufacturing and sales. Its products mainly include lithium battery separators and water treatment membranes. In the construction of intelligent production, virtual server technology is the core to implement digital transformation.

Wuxi Energy New Materials 16 production

lines are all using the world's advanced equipment, intelligent and automation

equipment as the basis, integration of ERP, MES, WMS, MWMS, QMS, EDI, VMI, data

acquisition, automatic warehouse system and other information platforms, to

achieve the "digital product expression, manufacturing process

information, logistics equipment intelligent" diaphragm enterprise

ecological model. A diaphragm intelligent manufacturing factory with

"agile product manufacturing, lean production management and excellent

product quality" has been built.

Intelligent performance of Wuxi Energy New

Materials

1. Realizing device interconnection

Through the interconnection of equipment,

the digital equipment such as CNC machine tools, heat treatment equipment and

robots in the workshop can realize program network communication, remote data

collection, centralized program management, big data analysis, visual display,

intelligent decision support, etc. The equipment will be upgraded from the

previous stand-alone mode to the digital, networked, intelligent management

mode.

2. Collaborative production and

efficient operation

Through the planning, production

scheduling, labor dispatching, materials, quality, decision-making and other

modules in the system, the information system is used as a means to realize the

sharing and collaboration of various information, and achieve the precision

planning, lean production, visual display, and fine management at the workshop

level.

The previous "serial production" is

transformed into "parallel" collaborative production mode to achieve

"one flow" production. Before the workpiece is transferred to the

equipment, the processing program and other technical documents, fixture and

other production resources are all ready, greatly reducing the waiting time of

equipment.

3. Fusion of reality and virtuality,

adding value in the flow of data

Yunnan Energy New Materials changes the

traditional manufacturing mode, achieve virtual and physical deep integration,

virtual and real mapping, mutual promotion. All positions and equipment in the

workshop are integrated into the whole information system, which is

characterized by the orderly flow of data and takes efficient and high-quality

production as the core. All links of human, machine, material, method,

environment and measurement are integrated with each other. Based on the

digital, networked and intelligent management system, managers can achieve

"visible, clear and correct". It has realized the smart production

mode of agility, high efficiency, high quality, low cost, green and

collaborative.

4. Intelligent manufacturing, cost

reduction and efficiency increase

Through the comprehensive scientific

management and control of the workshop, the scientific planning of the

workshop, the collaboration of the production process, the deep integration of

the production equipment and the information system are greatly improved, and

the transparent and quantitative management is carried out on the basis of big

data analysis and decision support, which significantly improves the production

efficiency, product quality and production cost of the enterprise.

The future is in store. As the benchmark factory of new energy system under Yunnan Energy New Materials, Wuxi Energy New Materials constantly improves its product strength and delivery capacity, and has become the main factory under Yunnan Energy New Materials. Under the strategic deployment of Yunnan Energy New Materials Shares and the group's R&D capability, Wuxi Energy New Materials will provide higher quality products and services for domestic and foreign lithium battery enterprises.

近日,江苏省工业和信息化厅联合省财政厅组织开展了2022年省级智能制造示范车间认定工作,并公示2022年江苏省智能制造示范车间拟授牌名单,无锡恩捷新材料科技有限公司“高端动力锂电池隔离膜智能制造车间”入选。

什么是“智能车间”?

智能车间指的是制造类企业在车间中应用数字技术和智能装备,推动设备联网和生产环节数字化连接,实现生产数据贯通化、制造柔性化和管理智能化,从而达到降本提质增效的效果。

而“江苏省智能制造示范车间”要综合考核企业生产系统的设备先进水平、生产工序的自动化程度、生产工艺的精密化标准等众多因素,并按照“中国制造2025”标准及智能制造的发展要求,对企业做出权威评定。

无锡恩捷隶属于恩捷股份,是集技术开发、制造、销售于一体的新能源材料企业,产品以锂电池隔膜、水处理膜等为主。在智能化生产建设中以虚拟服务器技术为核心,实施数字化转型。

无锡恩捷16条产线皆采用全球先进装备,以智能化和自动化设备为基础,整合ERP、MES、WMS、MWMS、QMS、EDI、VMI、数据采集、自动仓系统等信息化平台,实现了“产品表达数字化、制造工艺信息化、物流装备智能化”的隔膜企业生态模式,构建了“敏捷的产品制造、精益的生产管理、过硬的产品质量”的隔膜智能制造工厂。

无锡恩捷的智能化表现

1、实现设备互通互联

通过设备的互联互通,将车间的数控机床、热处理设备、机器人等数字化设备实现程序网络通讯、数据远程采集、程序集中管理、大数据分析、可视化展现、智能化决策支持等。将设备由以前的单机工作模式,升级为数字化、网络化、智能化的管理模式。

2、协同生产,高效运转

通过系统中的计划、排产、派工、物料、质量、决策等模块,以信息化系统为手段,实现各种信息的共享与协同,做到车间层面精准化计划、精益化生产、可视化展现、精细化管理。

将以前“串行生产”转变为“并行”的协同生产模式,实现“一个流”的生产,工件转移到设备前,加工程序等技术文档、工装夹具等生产资源已经全部准备就绪,大大减少设备的等待时间。

3、虚实融合,数据在流动中增值

改变传统的制造模式,做到虚拟与物理深度融合,虚实精准映射、相互促进。车间各岗位、各设备都融于整个信息化系统,以数据有序流动为特征,以高效高质生产为核心,人、机、料、法、环、测各环节相互融合,基于数字化、网络化、智能化的管理系统,使管理者能做到“看得见,说得清,做得对”,实现了敏捷、高效、高质、低成本、绿色、协同的智巧化生产模式。

4、智能制造,降本增效

通过对车间全面的科学管控,大幅度提升车间计划科学性、生产过程协同性、生产设备与信息化系统的深度融合度,并在大数据分析与决策支持的基础上进行透明化、量化管理,对企业生产效率、产品质量、生产成本等方面有明显改善。

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报