The new production base of Audi FAW New energy vehicle project is located in Changchun, Jilin Province, which is Audi's first factory in China focusing on the production of pure electric models. The project is currently under intense construction and is scheduled to begin production by the end of 2024.

As a major project of mutually beneficial cooperation between China and Germany and actively embracing the wave of automobile industry change, Audi FAW new energy vehicle project vividly illustrates the new industrial form generated by high-quality development with advanced planning and design concepts and world-class construction quality.

In terms of the "dual carbon" goal, Audi FaW New Energy Automobile Co., Ltd. realizes carbon neutrality in vehicle production by introducing Audi Group strategy "Mission:Zero". In terms of the information construction of the smart factory, all the management, logistics and production processes of the project will be fully networked through the same information technology architecture. The factory will be filled with various intelligent production equipment, automatic welding, handling robots and other intelligent manufacturing equipment. Based on the above construction concept and planning, the project has put forward higher requirements for green environmental protection and roof envelope structure quality.

With the green and low-carbon development concept, high-quality and efficient product quality, solutions and system services, Oriental Yuhong has won high recognition from customers and builders. It provides the TPO single-layer roofing system with energy-saving, environmental protection, safety and reliability for the project, that is, the flexible roof enclosure system with single-layer TPO waterproof coil.

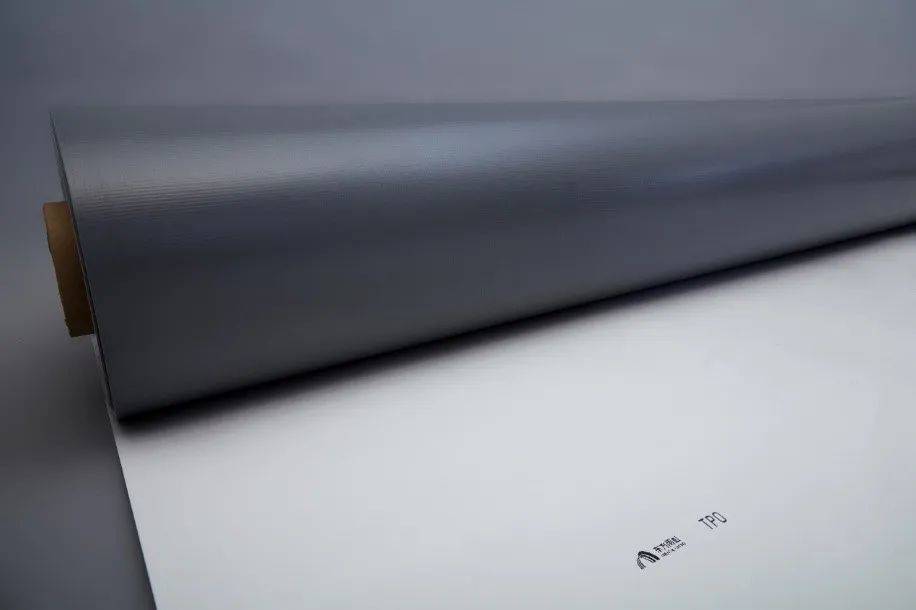

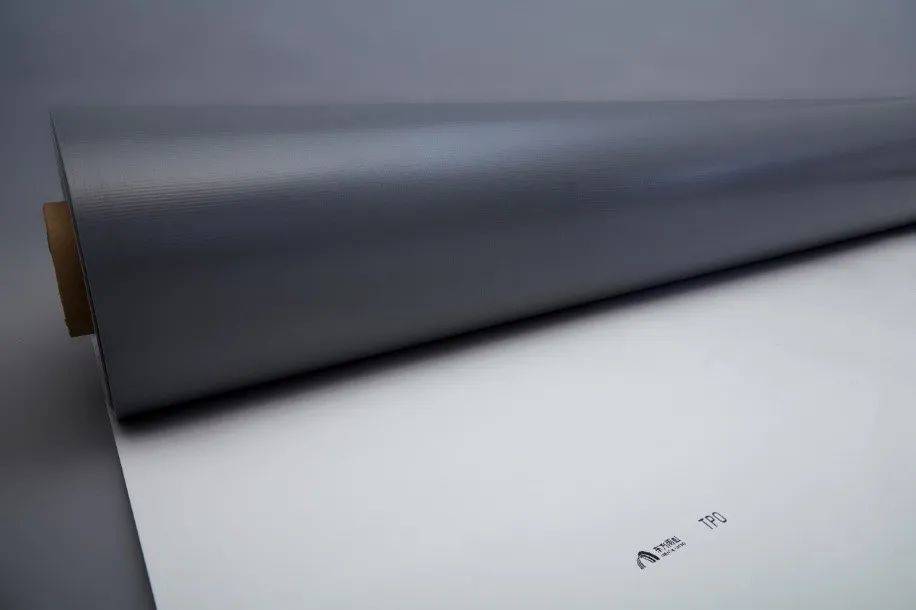

Oriental Yuhong thermoplastic polyolefin (TPO) waterproof coil

TPO waterproof coil, as a polymer waterproof coil widely used in long-span industrial buildings, has excellent weather resistance and durability, welding performance, environmental protection and energy saving and other technical advantages. The 1.8mm TPO waterproof coil selected by Audi FAW new energy vehicle project not only meets the practical application needs of the project, but also fully meets the technical requirements of the first class waterproof grade in the national standard "General Code for Waterproofing of Building and Municipal Engineering" issued by the Ministry of Housing and Urban-Rural Development on October 24.

During the construction process, Oriental Yuhong provided TPO waterproof coils for several single roofing waterproof system projects such as final assembly workshop, technology center, technology general corridor, joint power station, logistics distribution, battery workshop, painting workshop, etc. The cumulative total amount of TPO waterproof coils required by this construction project exceeded 60%. In addition, also contracted part of the single roof waterproof system engineering installation and construction content.

In the construction of various structural levels and detailed nodes within the waterproof, thermal insulation, steam insulation and other systems, Oriental Yuhong strictly complies with the standards and requirements of the Chinese and German owners, designers and general contractors on the basis of fully implementing the standardized construction specifications, so as to ensure the construction quality and construction nodes.

The non-perforated fasteners are arranged and fastened strictly according to the wind load calculation results

The waterproof membrane is neatly laid, and the

overlapping edges are welded by hot air

As a system provider of building materials, Oriental Yuhong adheres to the principle of quality first and environmental protection first. Supported by its own advantages and professional strength, Oriental Yuhong penetrates the sustainable development concept of green, environmental protection and energy saving throughout the whole process and every link of its development. Relying on TPO waterproof coil and waterproof system, Oriental Yuhong will further promote the wide application of energy-saving and environment-friendly high-quality products and system services in the roofing enclosure system and distributed photovoltaic field of industrial buildings, so as to give a boost to the green, low-carbon and high-quality development of industrial buildings.

奥迪一汽新能源汽车项目全新生产基地位于吉林省长春市,是奥迪在华第一个专注于生产纯电动车型的工厂。目前,项目正在紧张建设中,计划2024年底投产。

作为中德互惠合作、主动拥抱汽车产业变革浪潮的重大项目,奥迪一汽新能源汽车项目以先进的规划和设计理念,对标世界一流的建设质量,生动诠释了高质量发展催生的全新工业形态。

在“双碳”目标方面,奥迪一汽新能源汽车有限公司通过引入奥迪集团战略“零排放计划(Mission:Zero)”,实现汽车生产的碳中和。在智能工厂信息化建设方面,项目所有管理、物流和生产流程都将通过同一信息技术架构实现全面联网,厂房内遍布各类数智化生产设备、自动化焊接、搬运机器人等智能制造设备。基于以上建设理念与规划,项目对绿色环保以及屋面围护结构质量都提出了更高要求。

东方雨虹凭借绿色低碳的发展理念,优质高效的产品品质、解决方案与系统服务,赢得客户及建设方高度认可,为项目提供兼备节能环保、安全可靠等特性的TPO单层屋面系统,即采用单层TPO防水卷材的柔性屋面围护系统。

东方雨虹热塑性聚烯烃(TPO)防水卷材

TPO防水卷材,作为目前广泛应用于大跨度工业建筑的高分子防水卷材,具有优异的耐候性与耐久性,焊接性能、环保节能等技术优势。奥迪一汽新能源汽车项目选用的1.8mm TPO防水卷材,在满足工程实际应用需要的同时,完全符合10月24日住建部发布的国家标准《建筑与市政工程防水通用规范》中一级防水等级的技术要求。

在此次建设过程中,东方雨虹为总装车间、技术中心、技总通廊、联合动力站房、物流配送、电池车间、涂装车间等多个单体的屋面防水系统工程提供TPO防水卷材,累计总量超过此次建设工程所需TPO防水卷材总用量的60%。此外,还承包了部分单体屋面防水系统工程的安装施工内容。

在防水、保温、隔汽等系统内各个构造层次及细部节点的施工中,东方雨虹在全面贯彻标准化施工规范的基础上,严格履行中德双方业主、设计、总包单位的标准及要求,全力保障施工质量与建设节点。

无穿孔紧固件严格按照风荷载计算结果布置紧固

防水卷材整齐铺设,搭接边采用热风焊接

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报