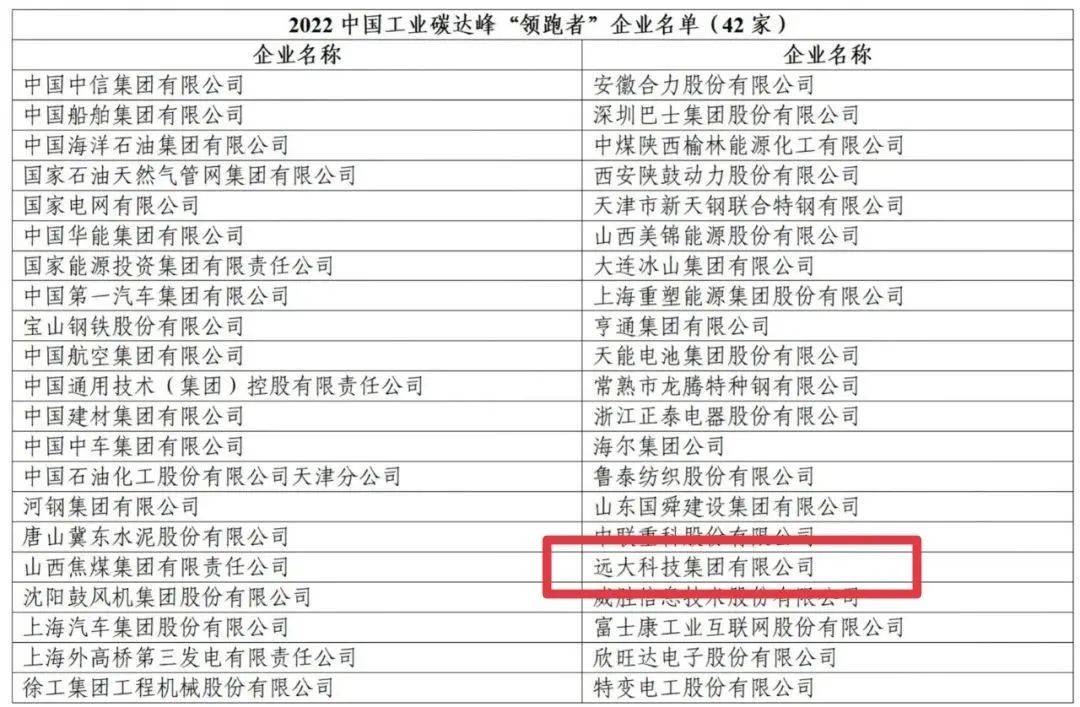

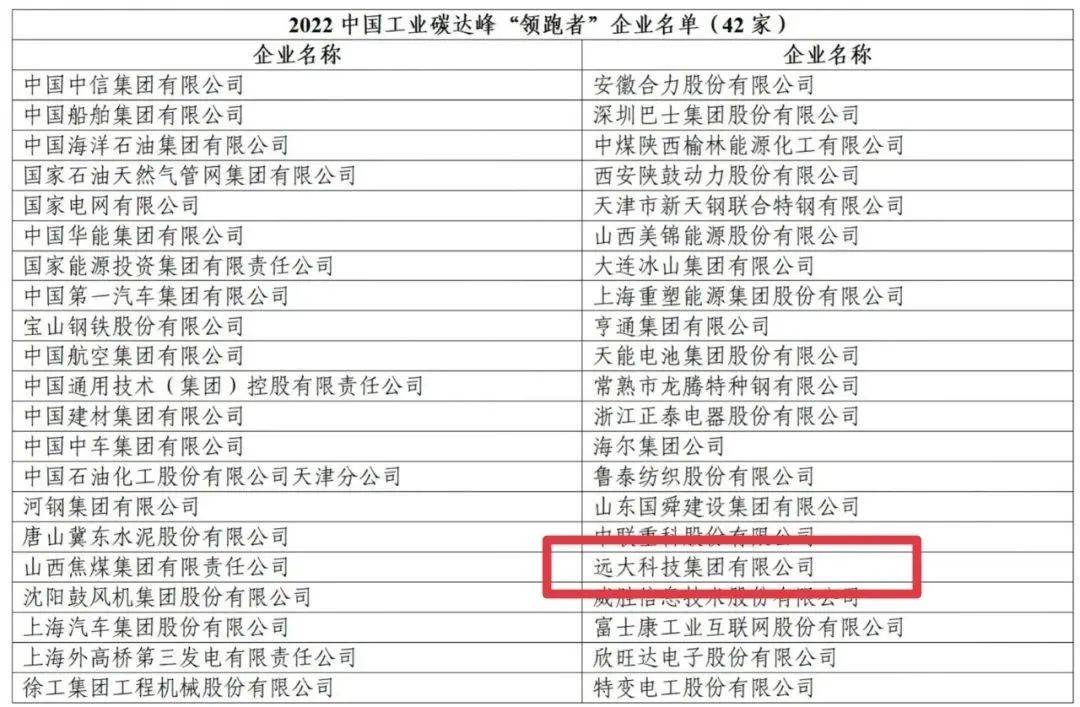

In order to thoroughly implement the decision-making and deployment of the CPC Central Committee and the State Council on "Doing a Good Job in Carbon Peaking and Carbon Neutrality", since March 2021, the China Federation of Industrial Economics has carried out in-depth research around the path of carbon peaking and carbon neutrality in key industries in China, and the research results have received the attention and instructions of relevant leading comrades of the state. In December 2022, the research results of China's first industrial carbon peaking "leader" enterprises were released, and 42 enterprises were selected, including 13 central enterprises, 12 local state-owned enterprises and 17 private enterprises/joint ventures. Based on its outstanding contribution in the field of industrial carbon peaking and its leading role in the field of green development, Broad Science and Technology Group stands out from nearly 300 leading enterprises and will continue to devote itself to the green low-carbon transformation and high-quality development of global industry.

With the mission of “For Humanity’s Future: Using original low carbon & durable technology for the earth. Using original clean & safe technology for humans.”, Broad Technology Group has originally developed hundreds of high-tech energy-saving products and services, many of which are effective in reducing carbon, helping to achieve the goal of "carbon peaking and carbon neutrality" in China.

Some achievements of Broad Technology Group's industrial carbon peaking:

Holon Building is a stainless steel factory building originally created by Broad. It adopts more than 10 energy-saving technologies with almost "crazy" perfectionism, which saves at least 5 times energy than conventional buildings, produces only 1% construction waste in the construction process, realizes 100% factory green production, and if necessary, the module can be disassembled and rebuilt in different places and realizes 100% recycling. The floor is made of super-strong and super-light "stainless steel core board", and the columns and beams are made of stainless steel profiles. The whole building does not use concrete, the structure, decoration, mechanical and electrical are 100% factory prefabricated, on-site bolt installation, at least 3 layers a day. Prefabricated modules are shipped in 40-foot container sizes for hassle-free, low-cost transportation around the world. After field installation, there is no column clearance of 11.7 X 4.8 meters, and the application is very flexible.

Broad Holon Building is designed, produced, accepted and operated in accordance with China's "Technical Standard for Near Zero Energy Consumption Buildings" and Germany's "Passive Housing Standard", which is the lowest energy consumption building except renewable energy. If we adopt the construction method of Broad Holon Building, we have the opportunity to reduce the world's carbon by 40%.

by Broad uses waste heat as energy for refrigeration and heating, which can effectively realize the energy saving and emission reduction of "turning waste into treasure". Broad has widely applied waste heat recovery technology in high energy consumption industries such as chemical industry, papermaking, iron and steel, and wine-making, comprehensively treating industrial emissions and greatly improving economic benefits.

The data center energy station of Hunan Radio and Television Program Production Headquarters Base uses non-electric air conditioning to deeply recover the waste heat (flue gas and hot water) of small and medium-sized gas-fired generators for free refrigeration and heating, which increases the comprehensive energy utilization efficiency of the data center from 44.8% to 88%, reduces the PUE value (power efficiency) to about 1.2, and reduces carbon dioxide emissions annually. It is equivalent to planting 280000 trees, reaching the national advanced green data center standard, and achieving the goal of energy-saving, environment-friendly and efficient project construction.

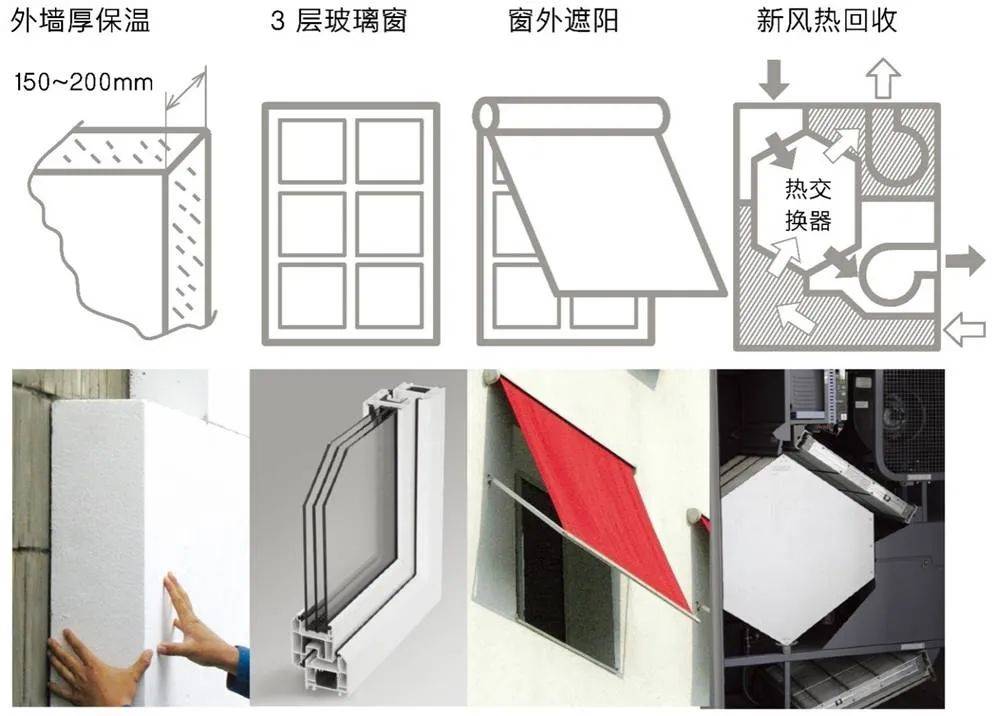

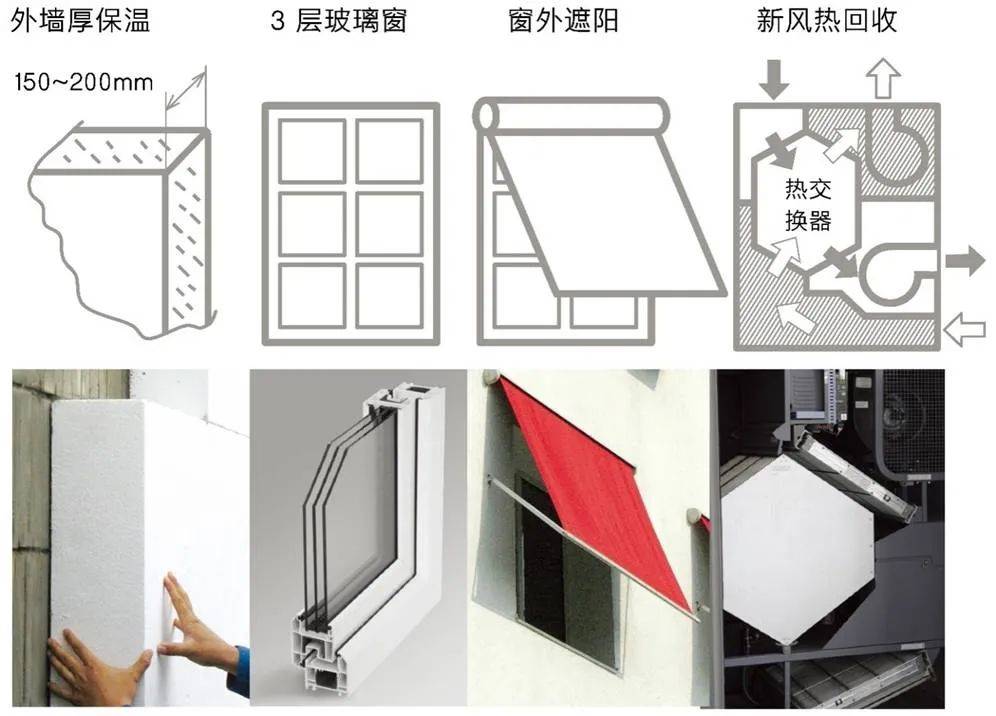

BASF project selects BDH800, a single-effect hot water non-electric air conditioner, and uses steam condensate as the driving heat source to produce low-temperature refrigerant water for the cooling of cyclohexane production process, with an annual emission reduction of 1940 tons of carbon dioxide, equivalent to planting 110000 trees. It not only realizes energy saving and emission reduction, but also guarantees the uninterrupted operation of the project throughout the year. 3. The energy consumption of existing buildings and related industries is close to 50% of the total social energy consumption, which is the invisible "champion" of carbon emissions, and zero energy consumption of buildings is the key to achieve "carbon peaking and carbon neutrality". Broad adopts four main energy-saving technologies, namely, thick external wall insulation, multi-layer glass plastic frame window, sunshade outside the window, fresh air heat recovery, and equipped with thermal insulation curtain inside the window and wind power generation, which can achieve nearly zero energy consumption of the building. Since 2008, Broad has carried out energy-saving renovation of all residential and office buildings in Broad City. On the premise of ensuring indoor temperature and humidity and improving air cleanliness, it has reduced air conditioning energy consumption and carbon emissions by more than 80% compared with before the renovation.

The World Health Organization (WHO) defines building cross-contamination as "sick building syndrome", which is regarded as a major global public health threat, and Broad Clean Fresh Air Fan has eliminated this threat. Broad clean fresh air fan adopts 100% fresh air technology, which can filter out more than 99.9% of PM2.5 in fresh air through electrostatic dust removal and high efficiency filter, so that indoor air is 100 times cleaner than outdoor air. At the same time, it is equipped with high efficiency heat recovery device, which can recover 80% of the energy in exhaust air. Even if 100% fresh air is introduced from outdoor, it consumes very little energy, completely eliminating cross-contamination of buildings.

EMC is an important business tool for energy conservation and emission reduction in industrial projects, which solves the problems of project investment, technology and management. Broad is the pioneer and leader of China's building central air-conditioning contract energy management and regional energy. It has built and operated hundreds of gas-fired distributed energy and multi-energy complementary regional energy projects, with a total operating area of nearly 80 million square meters and an annual emission reduction of 1.5 million tons of carbon dioxide.

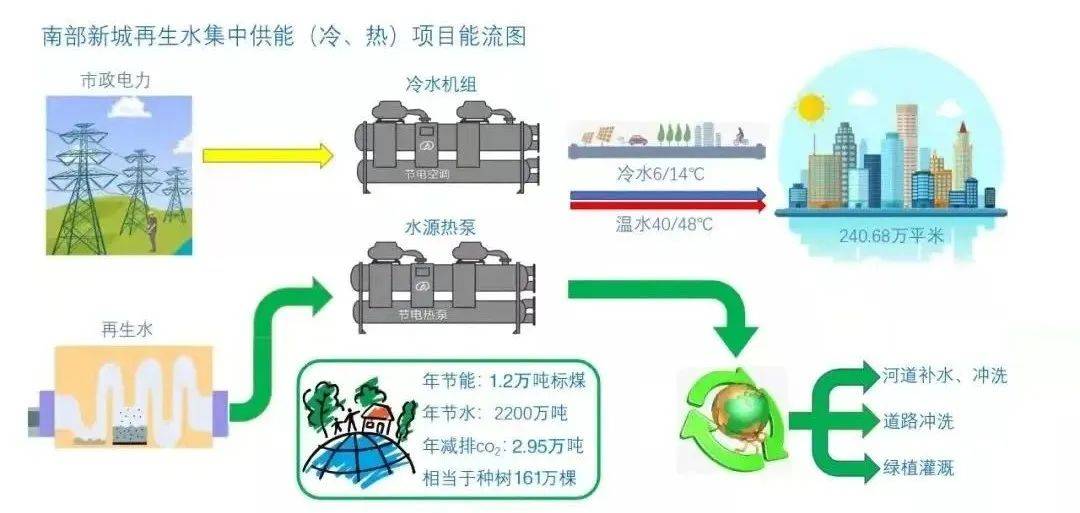

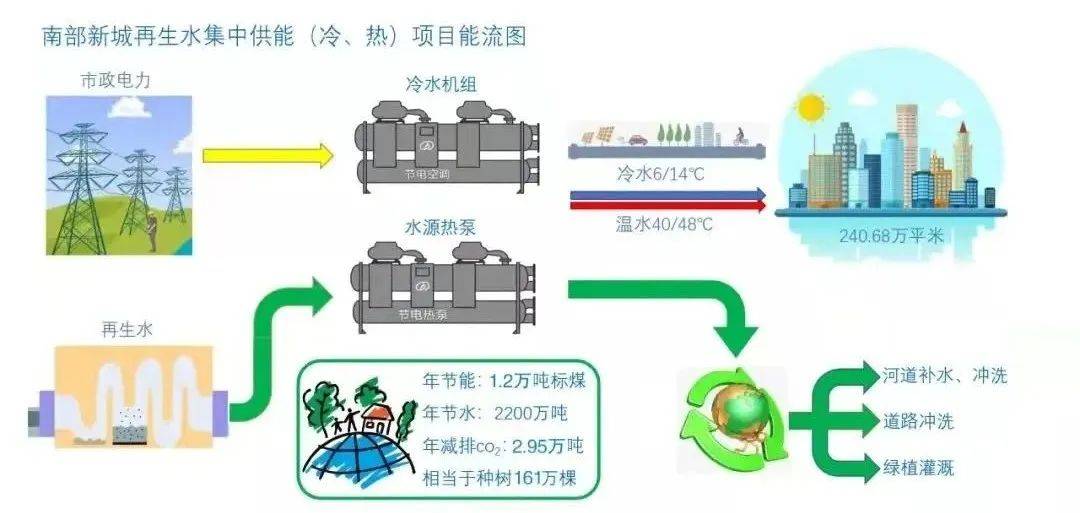

The heating and cooling project of 2.4 million square meters of public buildings in Nanjing Southern New Town adopts Broad Energy Management Contract, which can save 70% of electricity, 22 million tons of water per year and 29.5 million tons of carbon dioxide per year.

The original vacuum negative pressure distillation technology to separate the substances with different densities from waste mineral oil (including social source waste oil, industrial source waste oil, oily wastewater, waste emulsion, sludge and oily waste, etc.) In the environment of high temperature, vacuum and negative pressure, and reprocess these substances through double solvent refining technology. Finally, different types of lubricant base oils (7SSN, 150SN, 250SN, 350SN) were extracted, and the comprehensive utilization rate reached 97%.

为深入贯彻落实党中央、国务院关于“做好碳达峰、碳中和工作”的决策部署,2021年3月起,中国工业经济联合会围绕我国重点行业碳达峰碳中和实现路径开展深入调研,研究成果获得国家有关领导同志的关注与批示。2022年12月,中国首届工业碳达峰“领跑者”企业研究成果发布,共有42家企业入选,其中中央企业13家,地方国企12家,民营企业/合资企业17家。正是基于在工业碳达峰领域的杰出贡献和绿色发展领域的引领作用,远大科技集团从近300家头部企业中脱颖而出,将持续致力于全球工业绿色低碳转型与高质量发展。

远大科技集团以“为了人类未来:用原始创新的节能、耐久科技,保护地球家园;用原始创新的洁净、安全科技,保护人类生命”为使命,原创性地开发了上百种高科技节能产品和服务,多项产品、技术及服务均有效减碳、降碳,助力我国“碳达峰碳中和”目标的实现。

远大科技集团工业碳达峰部分成果:

活楼是远大独创的不锈钢工厂化建筑,用近乎“疯狂”的完美主义采用10多项节能技术,比常规建筑至少节省5倍能源、建造过程中只产生1%的建筑垃圾、实现100%工厂化绿色生产,必要时模块可拆卸异地复建并实现100%回收利用。楼板采用远大独创超强超轻“不锈钢芯板”,柱梁采用不锈钢型材。整个建筑不用混凝土,结构、装修、机电100%工厂预制,现场螺栓安装,一天至少3层。预制模块按40呎集装箱尺寸运输,可无障碍、低成本运至世界各地。现场安装后无柱净空11.7x4.8米,应用极为灵活。

远大活楼按照中国《近零能耗建筑技术标准》、德国《被动房标准》进行设计、生产、验收和运行,是除可再生能源以外的最低能耗的建筑。如果采用远大活楼这种建造方式,有机会为世界减碳40%。

远大发明的非电空调以废热等为能源制冷采暖,能有效实现“变废为宝”的节能减排。远大已在化工、造纸、钢铁、酿酒等高能耗工业领域广泛应用了余热回收技术,对工业排放进行了综合治理,同时大幅提升了经济效益。

湖南广播电视台节目生产总部基地的数据中心能源站采用非电空调,深度回收中小型燃气发电机的余热(烟气和热水)免费制冷、制热,使数据中心能源综合利用效率从44.8%提升到88%,PUE值(电能使用效率)降至1.2左右,年减排二氧化碳约5100吨,相当于种树28万棵,达到国家先进绿色数据中心标准,实现节能型、环保型、高效型的项目建设目标。

巴斯夫项目选用远大单效热水非电空调BDH800,利用蒸汽冷凝水作为驱动热源,产生低温冷媒水用于环乙烷生产工艺冷却,年减排二氧化碳1940吨,相当于种树11万棵。既实现了节能减排,又保障了项目全年不间断运行。3. 既有建筑近零能耗改造建筑及相关产业能耗接近社会总能耗的50%,是隐形的碳排放“冠军”,建筑零能耗是实现“碳达峰碳中和”的关键。远大采用外墙厚保温、多层玻璃塑框窗、窗外遮阳、新风热回收等四项主要节能技术,再配备窗内隔热帘及风力发电,可达建筑近零能耗。远大自2008年起对远大城所有的居住办公建筑进行了节能改造,在保证室内温湿度、提高空气洁净度的前提下,比改造前降低空调能耗、减少碳排放80%以上。

世界卫生组织(WHO)将楼宇交叉污染定义为“病态楼宇综合症”,视作重大全球性公共卫生威胁,而远大洁净新风机使这一威胁得以解除。远大洁净新风机采用100%新风技术,通过静电除尘及高效过滤器可将新风中PM2.5过滤掉99.9%以上,使室内空气比室外洁净100倍,同时配置了高效热回收装置,可回收排风中80%的能量,即使100%从室外引入新鲜空气,也极少消耗能源,彻底杜绝楼宇交叉污染。

合同能源管理是工业项目节能减排的重要商务手段,解决了项目投资和技术、管理等问题。远大是中国建筑中央空调合同能源管理和区域能源的开拓者和领军者,已建成并运营上百项燃气分布式能源和多能互补型区域能源项目,总运行面积近8000万平米,年减排二氧化碳150万吨。

南京南部新城240万平米公共建筑供热供冷项目,采用远大合同能源管理,可节省电力70%,节水2200万吨/年,减排二氧化碳2.95万吨/年。

远大采用独创的真空负压蒸馏技术,将废矿物油(含社会源废油、工业源废油、含油废水、废乳化液、油泥及含油废物等)在高温真空负压的环境下分离其中密度不同的物质,通过双溶剂精制技术对这些物质进行再次加工,进一步分离杂质,最后提炼出不同型号的润滑油基础油(7SSN、150SN、250SN、350SN),综合利用率达97%。

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报