On

January 10, Mingyang Intelligence officially released MySE18.X-28X, the

world's largest offshore wind turbine of 18 MW, and the world's largest

floating offshore wind turbine MySE16.X-260. The research and development of

MySE18.X-28X is an important measure for Mingyang, as a leader in the

offshore wind power industry, to actively promote the grid parity of offshore

wind power, reduce the construction cost of offshore wind power, and lay out

the far-reaching development of the sea.

Zhang Qiying, President and Chief Technology Officer of Mingyang Intelligence, introduced the MySE18.X-28X unit.

MySE18.X-28X unit has made innovations and breakthroughs on the basis of continuing Mingyang semi-direct drive technology route, with the characteristics of "modularization, lightweight, high efficiency and high reliability", which makes the performance of the unit to the extreme while reducing the weight, cost and manufacturing process difficulty of key components. The R&D team adopts innovative aerodynamic technology based on cross-domain integration of blades, which can improve the efficiency of power generation by 2%, avoid instability, and reduce the load of the whole machine under extreme conditions.

The newly released MySE18.X-28X unit inherits a series of intelligent design genes. The wind turbine adopts holographic perception MPC technology and digital twin DTC technology, which can realize laser radar perception over 1000 meters and camera perception over 600 meters, thus making the measurement data more accurate and the unit safer. Based on the WMC control technology of field group wake, the power generation of the whole wind turbine can be increased by 3%.

On the day of release, Jianheng Certification Center issued MySE18.X-28X unit design certification certificate for Mingyang technical team, representing that the unit design scheme has been recognized by the industry.

At the same time, the MySE16.X-260 floating unit off the line on the same day is a blockbuster product launched by Mingyang. The unit inherits the advantages of Mingyang's leading anti-typhoon technology. Based on the design considerations of typhoon, extreme waves and other harsh environments in the South China Sea, the extreme wind, wave and current conditions once in 50 years are selected for design, which can withstand up to 17 typhoons. When the annual average wind speed is 8.5m/s, the annual power generation of the unit can reach 67 million degrees, which is equivalent to the total annual electricity consumption of 80000 Chinese residents. The unit adopts the world's leading floating control technology and carries the world's leading floating body motion control strategy, which enables the floating unit to adapt to complex operating environments such as wind, wave and current.

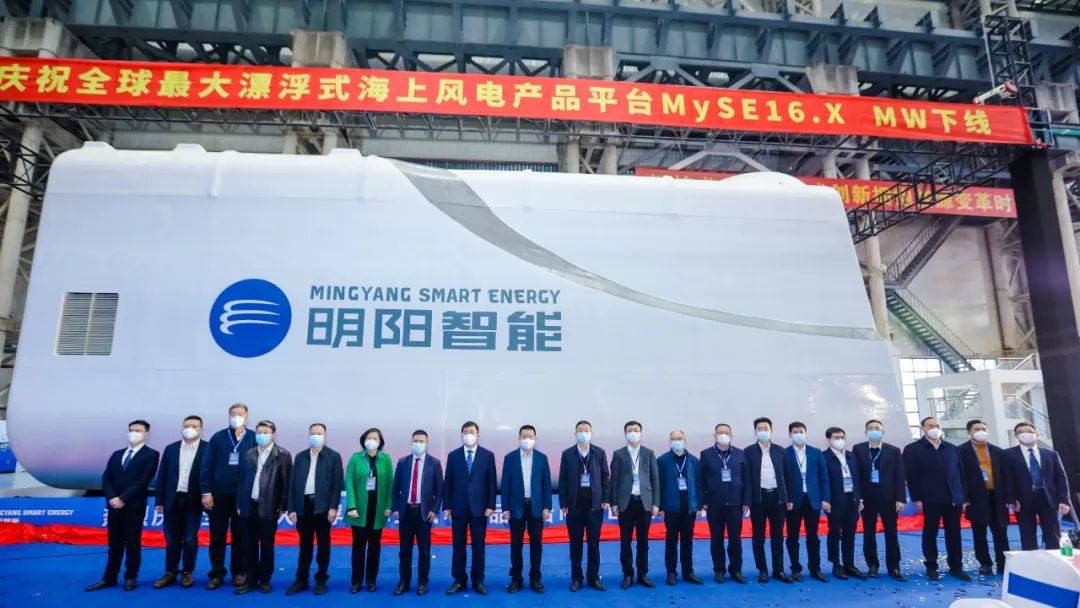

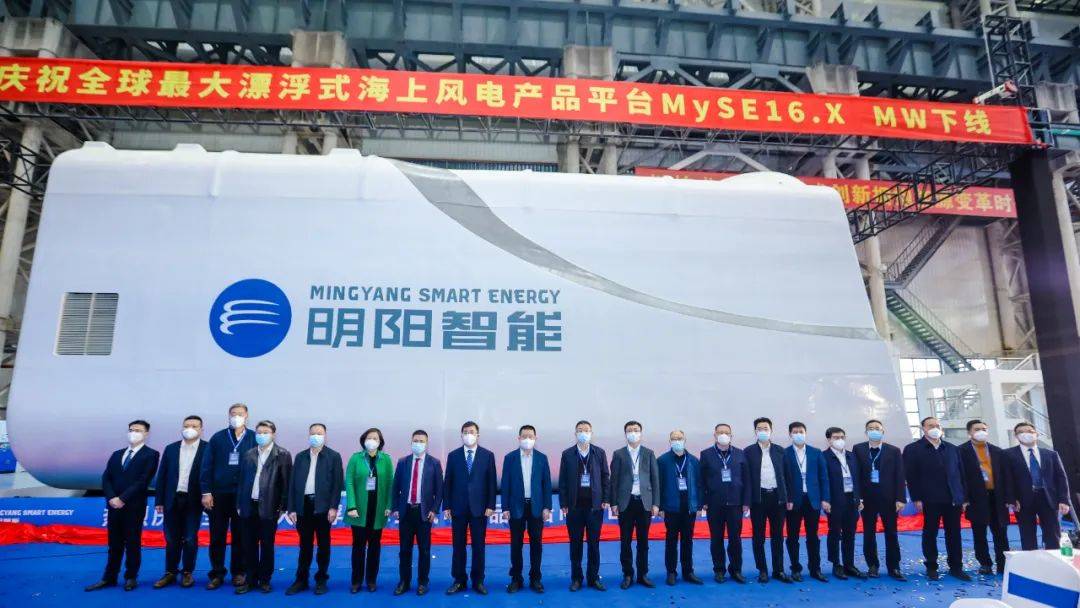

MySE16.X-260, the world's largest floating offshore wind turbine, is officially offline

MySE260, the world's largest and longest offshore typhoon-resistant blade of Mingyang Intelligence

The person in charge of MySE16.X-260 wind turbine products disclosed that the offline of wind turbine products has further enhanced the manufacturing capacity of the whole industry chain of domestic high-end equipment, including large-scale yaw pitch bearing manufacturing, gearbox and generator manufacturing, and large-scale casting manufacturing. It is understood that the MySE16.X-260 wind turbine is scheduled to be put into operation in Norwegian waters with a design depth of 200 meters and an offshore distance of 10 kilometers this year.

Under the background of offshore wind power grid parity at home and abroad, large-scale units have become an important way to reduce the construction cost of offshore wind power and improve the economic benefits. As the leader of large MW wind turbine technology, Mingyang now has 8.5 ~ 18 MW series product lines suitable for various wind conditions and wave environment conditions, and has developed 5.5MW, 7.25 MW, 11 MW, 16 MW and 16.6MW series floating wind turbines suitable for deep sea areas.

At present, China's offshore wind power shoulders the triple mission of economic development, energy innovation and green low-carbon. As a global leader in semi-direct drive technology, Mingyang is committed to the development of large impeller and large MW wind turbines, greatly improving the utilization rate of regional wind resources through scientific and technological innovation, and contributing intelligent energy solutions to the world.

1月10日,明阳智能正式发布18兆瓦全球最大海上风电机组——MySE18.X-28X,并下线全球最大漂浮式海上风电机组MySE16.X-260。MySE18.X-28X的研发,是明阳作为海上风电行业领导者积极推动海上风电平价上网、降低海上风电建设成本、布局深远海发展的重要举措。

MySE18.X-28X机组将搭载超140米叶片,其叶轮直径超280米,最大扫风面积66052平方米,相当于9个足球场大小。发电能力方面,以粤东风资源条件(年平均风速8.5m/s)为例,该机组全年发电量可达8000万度,相当于减少二氧化碳排放6.6万吨,约等于9.6万居民的年总用电量。经济性方面,以100万千瓦的粤东风电场为例,MySE18.X-28X机组与目前市场13+MW级别机组相比,可减少18个机位数量,单位千瓦工程造价降低约800~1000元/kW。

明阳智能总裁兼首席技术官张启应介绍MySE18.X-28X机组

MySE18.X-28X机组在延续明阳半直驱技术路线的基础上进行了创新和突破,具有“模块化、轻量化、高效率、高可靠”的特点,使机组性能发挥到极致的同时降低了关键部件的重量、成本以及零部件制造工艺难度。研发团队采用基于跨领域融合叶片气动创新技术,使得该机组叶片可提升2%发电效率,还能避免失稳,且极端工况下可降低整机载荷。

全新发布的MySE18.X-28X机组继承了一系列智慧化的设计基因。该风电机组采用全息感知MPC技术和数字孪生DTC技术,可实现激光雷达感知超1000米、摄像头感知超600米,从而使测量数据更精确,机组更安全。基于场群尾流WMC控制技术,整场风机发电量可提升3%。

发布当天,鉴衡认证中心为明阳技术团队颁发了MySE18.X-28X机组设计认证证书,代表该机组设计方案已获得行业认可。

同时,当天下线的MySE16.X-260漂浮式机组同属明阳推出的重磅产品。机组继承明阳领先的抗台风技术优势,基于中国南海台风、极端海浪等恶劣环境设计考虑,选用50年一遇的极端风浪流工况设计,最高可抵御17级台风。在年平均风速8.5m/s情况下,该机组全年发电量可达6700万度,相当于8万中国居民的年总用电量。该机组采用全球领先的漂浮式控制技术,搭载全球领先的浮体运动控制策略,使得漂浮式机组能适应风、浪、流等复杂运行环境。

全球最大漂浮式海上风电机组MySE16.X-260正式下线

明阳智能全球最大最长的海上抗台风型叶片——MySE260

MySE16.X-260风机产品负责人透露,风机产品的下线进一步提升了包括大型偏航变桨轴承制造、齿轮箱及发电机制造、大型铸件制造等在内的国内高端装备全产业链制造能力。据了解,MySE16.X-260风电机组计划于今年在设计水深200米、离岸距离10千米的挪威海域投运。

在国内外海上风电平价上网的大背景下,机组大型化成为降低海上风电建设成本、提高经济性收益的重要途径。明阳作为大兆瓦风机技术的领先者,现已具备适应各种风况、海浪环境条件的8.5~18MW系列产品线,并已研发适用于深远海区域的5.5MW、7.25MW、11MW、16MW、16.6MW系列漂浮式风机。

当前,中国海上风电肩负经济发展、能源创新、绿色低碳三重使命。作为全球半直驱技术的领导者,明阳致力于大叶轮、大兆瓦风电机组的开发,以科技创新大幅提升区域风资源利用率,为全球贡献智慧能源解决方案。

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报