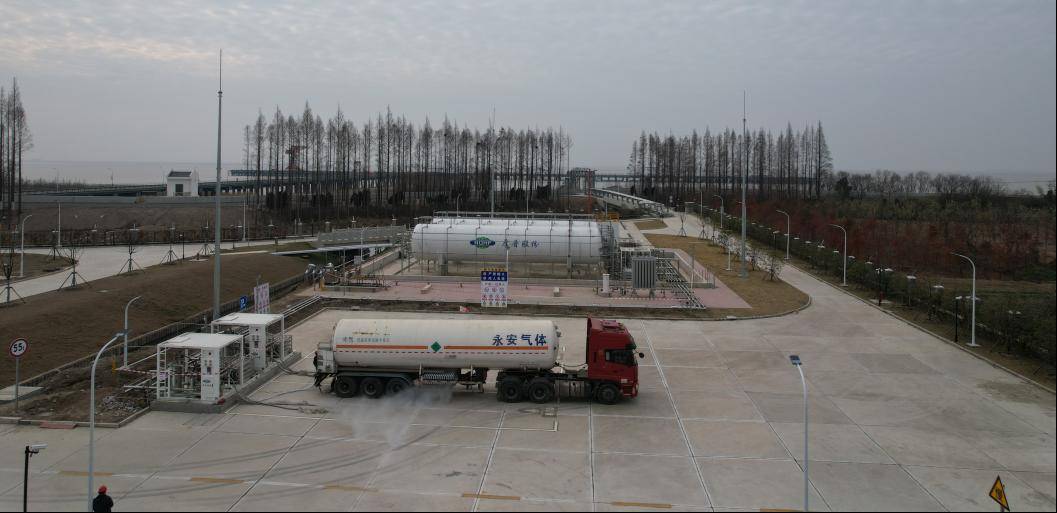

Recently, the ultra-long distance LNG filling system independently developed by Hopu Co., Ltd. has successfully passed the commissioning and acceptance of the LNG ship filling station at Chongming Island Public Cargo Terminal, realizing the first application of 900 meters ultra-long distance LNG ship filling station construction in China, setting a new record of long-distance filling of LNG ships in the domestic LNG industry, and leading the development of LNG ship filling industry. It provides a new idea for the design and construction of long-distance LNG ship filling station in China.

(Chongming Island Public Cargo Terminal LNG Vessel Filling Station)

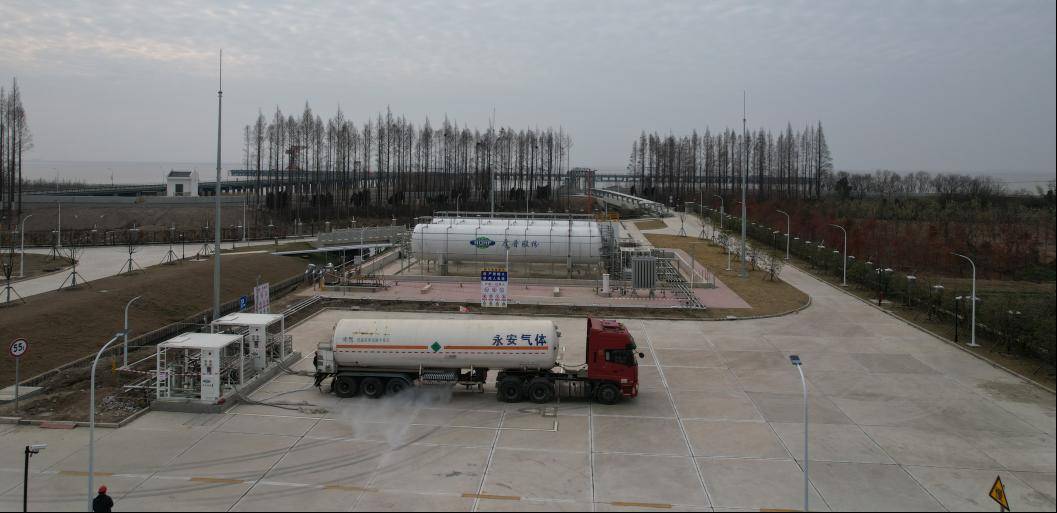

(Commissioning of LNG filling equipment completed)

Two LNG bunkering berths for 2,000-ton cargo ships are arranged at Chongming Island Public Cargo Terminal, which is the LNG ship bunkering station with the longest bunkering distance in China at present. The distance from the storage tank area to the bunkering terminal is about 900 meters. The vacuum pipeline is long, and the volume of the storage tank in the station yard is large. It has the characteristics of "long bunkering distance and large amount of BOG production". Considering submersible pump lift, station function, equipment performance and recycling, Houpu ultra-long distance LNG filling system innovatively realizes flexible switching between conventional and berth filling modes, and effectively controls BOG discharge in the filling process.

(Hopu ultra-long distance LNG filling system equipment)

(Unloading and commissioning)

Under the conventional filling mode, the tank liquid supply and vacuum pipeline transportation are adopted, the filling flow is large, and the BOG re-liquefaction recovery device is configured, which greatly reduces the discharge of BOG and is suitable for the peak season when there are many filling ships. When filling at the berth, the LNG tanker stops at the wharf for direct filling, which is suitable for the off-season when there are few ships to be filled. The two filling modes can be flexibly selected by customers, which will effectively reduce the generation of BOG during operation and improve the economy of site operation.

(Commissioning of filling skid)

Chongming Island Public Cargo Terminal is a comprehensive public cargo terminal that guarantees the materials needed for the operation of Chongming Island and the people's livelihood. Its main functions include: ship fuel filling, ship LNG filling, and cargo transportation on Chongming Island. At present, it mainly solves the filling problems of ships belonging to Shanghai Chongming Passenger Shipping Co., Ltd. and Shanghai Passenger Shipping Co., Ltd. In the long run, it will undertake ship refueling, gas filling and dangerous goods roll-on and roll-off operations throughout the island. After the completion of the LNG ship filling station, the layout of LNG power ship filling points in Shanghai will be further optimized, and the ecological priority and green development of the Yangtze River Estuary will be promoted.

(Chongming Island Public Cargo Terminal LNG Filling Station)

It is understood that among the nine LNG ship filling stations planned and constructed in the Yangtze River trunk line basin, from Zigui in the upper reaches of Hubei Province to Ezhou in the middle reaches of Hubei Province, Chenglingji in Yueyang, Hunan Province, to Wuhu in Anhui Province, Baguazhou in Nanjing and Chongming Island in Shanghai in the lower reaches of the Yangtze River, Hopu shares provide equipment and services. The successful acceptance of Chongming Island public cargo terminal LNG filling station indicates that Hopu has successfully helped build seven LNG filling stations in the Yangtze River trunk line basin, which will inject strong impetus into the development of low-carbon logistics and green shipping in the Yangtze River basin.

With the mature application of Houpu ultra-long distance LNG filling system in Chongming Island public cargo terminal LNG filling station, it marks a new breakthrough in China's LNG ship filling technology, and will set a new benchmark for China's ship LNG industry. As the earliest R&D and construction enterprise involved in LNG filling station on water in China, in the future, Hopu will closely follow the national "double carbon" goal and the strategic deployment of green development, actively exert Hopu's rich experience in LNG ship project implementation and LNG ship equipment research and development, construction EPC services and operation management. Provide more competitive solutions for the market, and continue to promote the high-quality development of green transportation and green water transport!

近日,由厚普股份自主研发的超长距离LNG加注系统在崇明岛公共货运码头LNG船舶加注站顺利通过调试验收,实现了国内900米超长距离LNG船舶加注站建设的首例应用,创下了国内LNG行业船舶远距离加注的新纪录,引领了LNG船舶加注行业发展,为我国长距离LNG船舶加注场站的设计建设提供了新的思路方案。

(崇明岛公共货运码头LNG船舶加注站)

(LNG加注设备调试完成)

崇明岛公共货运码头布置2个2000吨级货船LNG加注泊位,是目前国内加注距离最长的LNG船舶加注站,其储罐区域到加注码头约900米,真空管线长,站场储罐的容积大,具有“加注距离长,BOG产生量多”等特点。厚普超长距离LNG加注系统,从潜液泵扬程、站场功能、设备性能、回收利用四方面综合考虑,开创性实现了常规、泊位两种模式灵活切换加注,有效控制了加注过程的BOG排放。

(厚普超长距离LNG加注系统设备)

(卸车调试)

常规加注模式下,采用储罐供液与真空管路输送,加注流量大,配置BOG再液化回收装置,极大的减少BOG的排放,适用于受注船多的旺季。泊位加注时,LNG槽车停靠码头直接充装加注,适用于受注船少的淡季。两种加注模式,可供客户灵活选择,将有效降低运营期间BOG的生成量,提升站点运营的经济性。

(加注橇调试)

崇明岛公共货运码头是保障崇明岛城市运行和民生所需物资的综合性公共货运码头,主要功能包括:船舶燃油加注、船舶LNG加注、崇明本岛货物运输,目前主要解决上海崇明客运轮船有限公司及上海市客运轮船有限公司所属船舶的加注问题,远期将承担全岛的船舶加油、加气和包装件危险品滚装作业。该码头LNG船舶加注站建成后,将进一步优化上海市液化天然气动力船舶加注点布局,推动长江口生态优先绿色发展。

(崇明岛公共货运码头LNG加注站)

据了解,目前长江干线流域规划建设的9座LNG船舶加注站中,从上游湖北秭归到中游湖北鄂州、湖南岳阳城陵矶,再到长江下游安徽芜湖、南京八卦洲、上海崇明岛等地LNG船舶加注站均由厚普股份提供设备与服务。崇明岛公共货运码头LNG加注站的顺利验收,标志着厚普股份已成功助力长江干线流域7座LNG加注站建成落地,将为长江流域低碳物流、绿色航运的发展注入强劲的动力。

随着厚普超长距离LNG加注系统的在崇明岛公共货运码头LNG加注站的成熟应用,标志着我国LNG船舶加注技术取得新的突破进展,将为我国船舶LNG行业树立一个新标杆。作为国内最早涉足水上LNG加注站的研发及建造企业,未来,厚普股份将紧跟国家“双碳”目标与绿色发展的战略部署,积极发挥厚普丰富的LNG船舶项目实施经验与LNG船舶装备研发、施工EPC服务及运营管理的领先优势,一如既往地聚焦客户关注与行业痛点,为市场提供更有竞争力的解决方案,持续推动绿色交通、绿色水运的高质量发展!

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报