On October 29, the 17th China Corporate Social Responsibility Forum and the selection of "Responsible Enterprises in 2021" sponsored by China News Agency and China News Weekly were held in Beijing. Among them, Monalisa was awarded the "Responsible Enterprise of 2021".

Since its inception in 2005, the International Forum on Corporate Social Responsibility has become a platform with a long history, high-level government attendance and great influence in the field of social responsibility in China. Through the selection of "Responsible Enterprise of the Year" for 17 consecutive years, it has continuously set up a model of social responsibility for Chinese enterprises and continuously led the development of the frontier practice of corporate social responsibility.

According to the organizers, the selection of the award-winning enterprises was finalized through the evaluation of comprehensive professional support agencies, online public voting, media representatives and expert comments of professional steering committees. The award selection is highly professional, impartial and authoritative.

With years of active performance in the field of social responsibility and positive action in promoting low-carbon green development in 2021, Monalisa once again won the honor of "responsible enterprise". In the same period, Sinopec, Green Osmanthus Country Garden, BMW, Tencent and other well-known enterprises at home and abroad also won the award.

"Achieve carbon peaking by 2030 and carbon neutrality by 2060." With the continuous acceleration of green development, all walks of life have gradually found their roles in this great change.

Promoting the technological upgrading of intelligent manufacturing, optimizing the energy structure, speeding up the iterative process of green products, taking various measures simultaneously, treating both symptoms and symptoms, and doing a good job in environmental protection management, as a green pioneer in the domestic building ceramics industry, Monalisa has been promoting the green development of building ceramics for more than ten years, and is creating a sustainable green intelligent manufacturing sample.

We must form a joint force in scientific and technological innovation, transformation and upgrading, and implement the specific measures of energy conservation, emission reduction and energy structure optimization into daily life and business activities by strengthening management.

Building ceramics is a typical resource and energy consumption enterprise. Faced with the double-carbon target, many enterprises have accelerated the pace of transformation and upgrading, increased energy structure adjustment, increased energy conservation and emission reduction efforts, increased pollution control efforts, and created a new model combining "intelligent manufacturing" and "green production".

In recent years, Monalisa has continued to upgrade the production line with green and intelligent technology. Through a series of intelligent technological transformation, such as continuous ball milling, intelligent spraying, seven-layer drying, energy-saving kiln and double-layer kiln, it has achieved low-carbon and environmental protection in the production process.

Five-conjoined continuous ball mill

slurry-making system

Solves the

problems of high power and low working efficiency of the traditional ball mill

It has the characteristics of high intelligence, high

precision, stable operation and remarkable energy-saving effect.

"4.0 Energy Efficiency Benchmarking Digital Intelligence Era" Kiln

A major breakthrough has been achieved in the comprehensive energy consumption of the whole line of 1.57 Nm ³ natural gas/㎡

Waste heat recovery heating system

A group of high-end firing equipment with digital intelligent management mode

Realizing full utilization of waste heat at the tail of the kiln

The use of clean energy and renewable energy is an important way to achieve carbon neutrality of energy. Monalisa Tengxian production base in Guangxi uses natural gas when it is allowed to burn coal to make gas. From 2019 to 2020, Qingyuan production base and Xiqiao production base have completed natural gas transformation successively, while Jiangxi production base is also planning natural gas transformation in an all-round way, so that all bases can implement clean fuel as far as possible. Build a clean, low-carbon, safe and efficient energy system.

Monalisa Intelligent Manufacturing Digital Center

Carbon emission is also a system project, and the whole production process is a system from the beginning to the end, which needs specific accounting and data support. The intelligent manufacturing data center built by Monalisa is based on digital design, digital construction and digital operation and maintenance, providing real-time and accurate carbon emission data for enterprise development.

At the same time, the big data management system runs through the whole production process, displaying the production status of each production line and each process online in real time, as well as the data of output, quality, energy consumption, power consumption and water consumption, which provides strong support for production scheduling and energy consumption monitoring.

Monalisa's continuously upgraded flue gas multi-pollutant synergistic system

All kinds of explorations and achievements are the epitome of Monalisa's positive response to the changing situation. Recently, in order to cope with the large power supply load gap in many places, Monalisa is speeding up the construction of four production base roof solar electronic panel projects for photovoltaic power generation.

The concept of energy saving and emission reduction not only stays at the manufacturing end, but also runs through the structural adjustment of building ceramics products, such as thin plates and rock plates. Since 2007, Monalisa has launched 1800 × 900 × 5.5 (mm) ceramic sheet and built the first dry-pressed ceramic sheet production line in China, which has led to the thinning of ceramic products in the industry and the reduction of resource consumption and emissions.

At this double-carbon moment, Monalisa has accelerated the exploration of ceramic sheet thinning technology and application fields, deepened the cooperation between industry, University and research, and promoted the green and low-carbon development of ceramic industry with technological innovation.

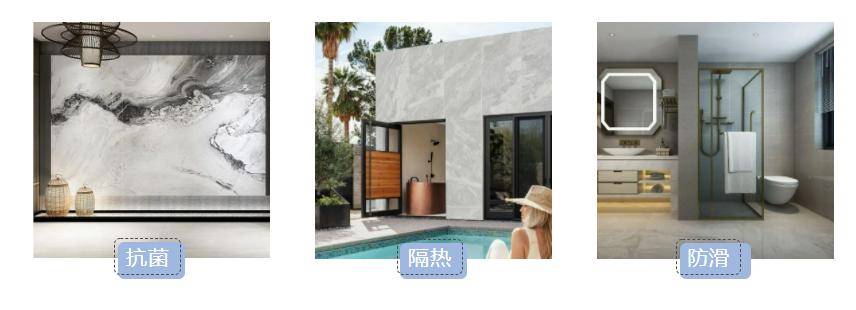

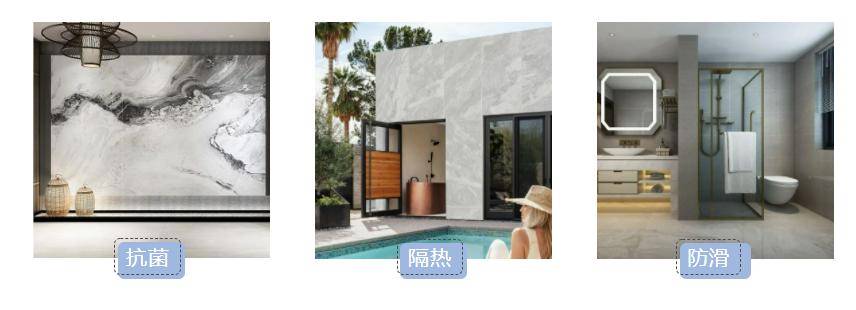

Innovative products such as thermal insulation and decoration integrated board, 3mm high toughness ceramic rock board and high heat reflectivity exterior wall ceramic tile (board) products have been launched iteratively to promote energy saving and emission reduction, and to promote low-carbon development from the product manufacturing and application side.

Achieving carbon peaking has become an inescapable historical mission of the industry, and it is also an urgent need to promote the safe and high-quality development of the building materials industry and accelerate the formation of a new pattern of "double-cycle" development.

Before the arrival of the whole carbon peaking, our enterprises should adjust their thinking first, that is, green first.

Monalisa has always put the concept of green environmental protection throughout the development of the group, "to become a resource-saving, environment-friendly leading enterprise", "environmental protection has no full stop, only comma", "with ultra-low emissions as the goal, the implementation of strict en terprise internal control standards" these three environmental protection concepts have become a ruler of all Monalisa people's words and deeds, penetrating into all aspects of production and operation. Promoting Monalisa to achieve green development, building a green industrial ecological chain, realizing resource and energy conservation, waste residue recycling, zero discharge of wastewater, and reflect the efficiency of circular economy and clean production.

10月29日,由中国新闻社、中国新闻周刊主办的第十七届中国企业社会责任论坛暨“2021年责任企业”评选在北京举行。其中,蒙娜丽莎荣获“2021年度责任企业”。

自2005年创立以来,企业社会责任国际论坛已成为 国内社会责任领域历史悠久、政府出席级别高、影响力大的平台 。通过连续十七年的“年度责任企业”评选,持续为中国企业树立社会责任典范,不断引领企业社会责任的前沿实践发展。

据主办方介绍,本次评选通过综合专业支持机构评估、网络公众投票、媒体代表和专业指导委员会专家评议意见等最终确定获奖企业,奖项评选极具专业性、公正性及权威性。

凭借多年来在社会责任领域的积极履责,以及2021年在推动低碳绿色发展中的积极行动,蒙娜丽莎再次获得“责任企业”荣誉。 同期获此奖项的还包括中石化、碧桂园、宝马、腾讯等国内外知名企业。

“2030年前实现碳达峰、2060年前实现碳中和。”绿色发展持续提速,各行各业在这场大变局中逐渐找到了自己的角色。

推进智能制造的技术升级,优化能源结构,加快绿色产品的迭代进程,多措并举、标本兼治,做好环保治理工作…… 作为国内建陶产业绿色先行者,蒙娜丽莎推进建陶绿色发展十余年,正在打造一个可持续的绿色智造样本。

必须在科技创新、转型升级上形成合力,通过加强管理,把节能减排优化能源结构的具体措施落实到日常的生活经营活动中。

建陶属于典型的资源能源消耗型企业。面对双碳目标的提出,不少企业已经加快了转型升级的步伐,加大能源结构调整、加大节能、减排力度,加大污染整治力度,打造“智能化制造”和“绿色生产”相结合的新模式。

近年来,蒙娜丽莎持续对生产线进行绿色智能整线提升,通过连续球磨、智能喷雾、7层干燥、节能窑炉、双层窑炉等一系列智能化技术改造,实现生产过程的低碳环保。

五连体连续球磨制浆系统

解决传统球磨机功率大、工作效率低的问题

实现智能化程度高、精度高、运行稳定、节能效果显著等特点

"4.0能效标杆数智时代"窑炉

实现了全线综合能耗1.57Nm³天然气/㎡的重大突破

余热回收加热系统

一组数字智能化管理模式的高端烧成装备

实现窑炉尾部余热全利用

使用清洁能源和可再生能源,实现能源碳中和的重要途径。蒙娜丽莎广西藤县生产基地,在当地允许烧煤制气的情况下全部采用天然气,2019年至2020年清远生产基地与西樵生产基地先后完成天然气改造,而江西生产基地也在全面着手天然气改造的规划,让所有的基地都尽可能实施清洁燃料,构建清洁低碳安全高效的能源体系。

蒙娜丽莎智能制造数字中心

碳排放也是体系工程,整个生产工艺从开始到结束就是一个系统,需要有具体的核算、数据支撑。而蒙娜丽莎建起的智能制造大数据中心,以数字设计、数字建造、数字运维为基础支撑,为企业发展提供实时、准确的碳排放数据。

与此同时,大数据管理系统贯穿生产全过程,实时在线显示每条生产线、每个工序的生产状况,以及产量、质量、耗能、耗电、耗水等数据,为生产制造排产、能耗监控等提供有力支撑。

蒙娜丽莎持续升级的烟气多种污染物协同系统

种种探索与成效,都是蒙娜丽莎积极应对变局的缩影。近期,为了应对多地出现较大供电负荷缺口,蒙娜丽莎目前正加快投建四个生产基地屋顶太阳能电子板项目,进行光伏发电。

节能减排的理念,不仅停留在生产制造端,还贯穿到建陶产品结构性调整中,薄板以及岩板就是典型代表。自2007年蒙娜丽莎推出1800×900×5.5(mm)陶瓷薄板,并建成中国首条干压陶瓷薄板生产线,带动行业陶瓷产品减薄,减少资源消耗和排放。

在这个双碳当口下,蒙娜丽莎更是加快陶瓷薄板减薄技术与应用领域的探索,深入推进产学研合作,以技术创新助力陶瓷行业绿色低碳发展。

保温装饰一体板、3mm高强韧陶瓷岩板、高热反射率外墙陶瓷砖(板)产品等助推节能减排的创新产品迭代推出,从产品制造、应用端推进低碳发展。

实现碳达峰已成为行业不可推卸的历史使命,也是推进建筑材料行业安全发展、高质量发展,加快形成“双循环”发展新格局的迫切需要。

在整个碳达峰来临之前,我们企业先调整自己的思路,即一定是绿色先行。

蒙娜丽莎一直以来将绿色环保理念贯穿集团发展始终,“成为资源节约型、环保友好型领军企业”、“环保没有句号,只有逗号”、“以超低排放为目标,执行严苛的企业内控标准”这三大环保理念成为所有蒙娜丽莎人言与行的一把尺,渗透到生产经营的各个环节,推动蒙娜丽莎实现绿色发展,构建起绿色产业生态链,实现资源能源节约、废渣循环利用、废水零排放,体现循环经济和清洁生产效能。

打造绿色低碳街区,奏响幸福美好生活最强音

10-18 · 来源:湖北省武汉市江汉区北湖街道环保社区 · 作者:湖北省武汉市江汉区北湖街道环保社区

“碳惠冰城”:东北首个市级平台的“双碳”实践与冰城示范

10-15 · 来源:哈尔滨产权交易所有限责任公司 · 作者:哈尔滨产权交易所有限责任公司

亚洲气候治理新篇章:中国公益代表团参访曼谷气候周,探索跨区域合作新路径

10-10 · 来源:公益时报 · 作者:公益时报