Project Overview

案例概述

In order to

implement the concept of sustainable development and respond to the national

call for "zero-waste cities", in October 2023, Yangtze River

Pharmaceutical Group initiated the construction of the first "Zero-Waste

Group" in the pharmaceutical industry of Jiangsu Province. Through

measures such as source reduction and recycling, the group aimed to enhance the

level of solid waste resource utilization and reduce environmental risks. The

construction of the "Zero-Waste Group" by Yangtze River

Pharmaceutical Group was based on 2023 as the base year. The "Yangtze

River Pharmaceutical Group Zero-Waste Group Construction Implementation Plan

(2024-2025)" was compiled and submitted to the environmental protection

department for record and approval. The implementation period was from January

2024 to December 2025, involving 9 factories within Jiangsu Province. By the

end of 2024, the coverage rate of clean production audits for normal production

factories of Yangtze River Pharmaceutical Group reached 100%; the reduction and

utilization of industrial solid waste was approximately 1,929 tons, generating

economic benefits of approximately 11.9 million yuan; the generation intensity

of industrial solid waste was reduced to 0.0478 tons per ten thousand yuan.

为践行可持续发展理念,响应国家“无废城市”建设号召,2023年10月,扬子江药业集团启动江苏省医药行业首家“无废集团”建设工作,通过源头减量、循环利用等方式,提高固体废物资源化利用水平,降低环境风险。扬子江药业集团“无废集团”建设工作是以2023年为基准年,编制了《扬子江药业集团“无废集团”建设实施方案(2024-2025)》,并报生态环境部门备案取得批复,实施时间为2024年1月至2025年12月,涉及江苏省省内9家工厂。截至2024年底,扬子江药业集团正常在产工厂清洁生产审核覆盖率100%;工业固体废物减量化、资源化约1929吨,产生经济效益约1190万元;工业固体废物产生强度降至0.0478吨/万元。

Company/Organization Profile

机构简介

Yangtze River

Pharmaceutical Group was founded in 1971. It has over ten factories and more

than 20,000 employees. Its products include both Chinese and Western medicines,

and it has expanded into the field of health care. It covers 15 therapeutic

areas and has a total of 565 specifications. Its marketing network covers all

provinces in China, and some of its products are exported to 42 countries and

regions around the world. It has established 4 national-level innovation

platforms and won 3 National Science and Technology Progress Awards. It has

successively won the China Quality Award Nomination Award, the EFQM Global

Award, and the National Excellent Intelligent Factory title. In line with the

Healthy China initiative, it is accelerating the layout of the integrated

development of medicine, healthcare, elderly care, food, and tourism, and is

moving towards the vision of becoming a leading and world-class pharmaceutical

and health care industry group in China.

扬子江药业集团创立于1971年,旗下十多家工厂,员工20000余名,产品中西药并举、拓展大健康领域,涉及15个治疗领域、累计565个品规,营销网络覆盖全国各省,部分产品远销全球42个国家和地区。建有4个国家级创新平台,获3项国家科技进步二等奖。相继荣获中国质量奖提名奖、EFQM全球奖、国家卓越级智能工厂等称号。与健康中国同频共振,加快布局药、医、养、食、游融合发展,向着“做中国领先、世界一流的医药健康产业集团”的愿景迈进。

Project Outcome

项目成果

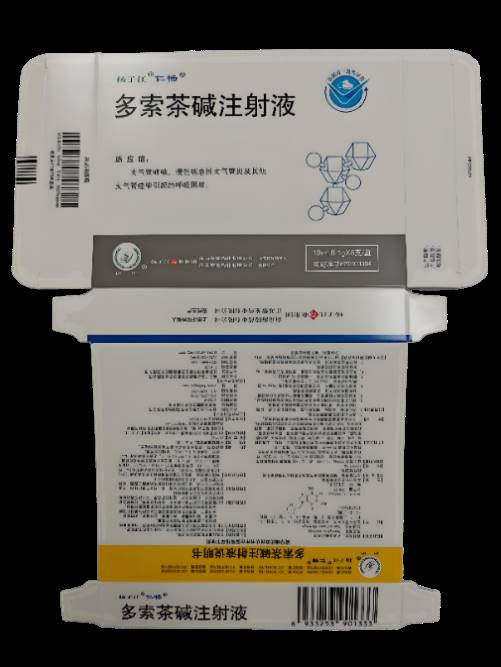

1. Reduction of

packaging materials

In order to

simultaneously meet the requirements of GMP and ESG, Yangtze River

Pharmaceutical Group has formulated the "Regulations on the Management of

Materials for Pharmaceutical Packaging of Yangtze River Pharmaceutical

Group", which clearly defines the full-process control requirements for

packaging material quality and acceptance, and systematically promotes the

reduction of packaging materials. For example, the factory directly prints the

content of the drug instructions on the packaging box to reduce the use of

instructions. Taking doxofylline injection as an example, it reduces the annual

paper usage by 10.84 tons. The factory reduces the specification of the blister

in the packaging of Lanqin Oral Liquid to reduce the use of plastic packaging

materials, reducing the annual plastic usage by 4.47 tons.

2. Organic solvent

recycling

As a key reaction

medium in pharmaceutical production, the single batch consumption of organic

solvents is usually several times that of the products. To reduce the solvent

usage, Yangtze Jiang Pharmaceutical Group, from the perspective of process

optimization, has taken effective measures to minimize the use of organic

solvents. For instance, in the specific drug production process of the factory,

methods such as distillation and concentration are employed to recover and

reuse the chemical solvents. In 2024, 1,477 tons of solvents were recycled and

reused, saving costs of 10.5 million yuan.

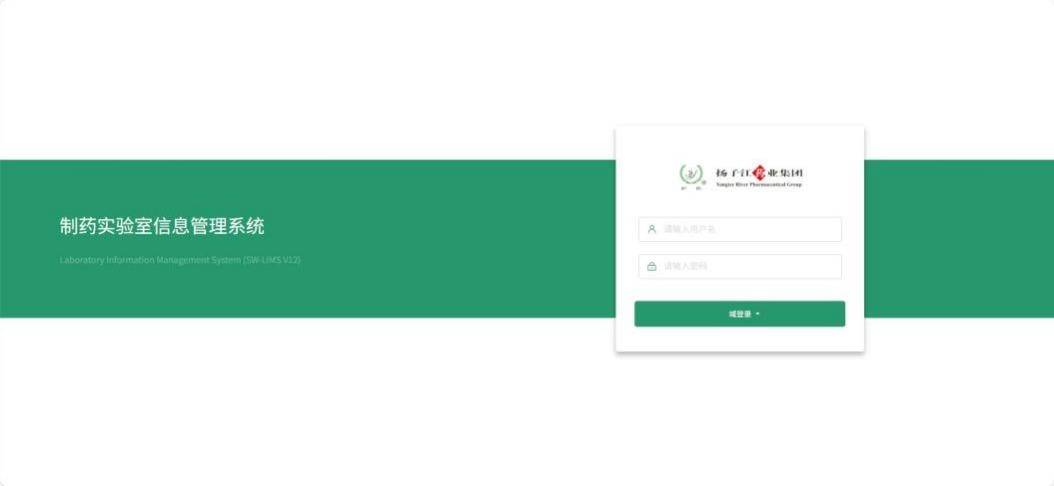

3. Paperless Office

To simplify the

daily management process in laboratories and promote the paperless

transformation of office work, in accordance with the unified deployment of

Yangtze River Pharmaceutical Group, each factory has adopted the ELN system

(Electronic Laboratory Notebook) to achieve digital collection, classification,

storage and retrieval of laboratory data, facilitating unified data management.

After the ELN system was put into use, each factory saved approximately 560,000

sheets of paper annually. By the end of 2024, Yangtze River Pharmaceutical

Group had extended the application of the ELN system to 10 of its factories,

achieving paperless operation in laboratories.

4. Solid Waste

Industrialization

Yangtze River

Pharmaceutical Group has comprehensively reviewed the current situation of

solid waste, fully tapped the potential for resource utilization of solid

waste, actively established cooperative relationships with solid waste disposal

units, and gradually increased the comprehensive utilization rate of solid

waste. For example: The group jointly explored the resource utilization path

with the activated carbon production unit, converting the previously

incinerated waste activated carbon into recycling and utilization. In 2024, 53

tons of waste activated carbon were recycled and utilized; the factory

entrusted a qualified unit to conduct a hazardous characteristic identification

of the sludge generated by the wastewater station. The identification result

was general industrial solid waste. After being registered with the

environmental protection department, it cooperated with the disposal unit to

utilize the drying technology to turn the sludge into a brick-making raw

material. In 2024, 87.1 tons of sludge were comprehensively utilized.

1、包材减量化

扬子江药业集团为同步满足GMP以及ESG等方面的相关要求,制定了《扬子江药业集团药品包装用材料管理规定》,明确了包材质量、验收等全流程管控要求,系统性推动包材减量。如:工厂将药品说明书内容直接印刷于包装盒上,减少说明书的使用,以多索茶碱注射液为例,年减少用纸量10.84吨;工厂降低蓝芩口服液包装中吸塑的规格,减少塑料包材的使用,年减少塑料用量4.47吨。

2、有机溶剂循环化

有机溶剂作为药品生产的关键反应介质,其单批次消耗量通常为产物的数倍。扬子江药业集团为降低溶剂用量,从生产工艺优化角度,采取有效措施减少有机溶剂的使用。如:工厂在特定药品生产过程中,采用蒸馏、浓缩等方式对化学溶剂进行回收再利用,2024年回收再利用溶剂1477吨,节约成本1050万元。

3、办公无纸化

为简化实验室日常管理流程、推进办公无纸化转型,根据扬子江药业集团统一部署,各工厂运用ELN系统(电子实验室记录本),实现实验室数据的数字化采集、分类、储存和提取,便于数据的统一管理。ELN系统投用后,以单个工厂计,每年节约用纸约56万张。截至2024年底,扬子江药业集团已将ELN系统推广应用至旗下10家工厂,实现实验室无纸化运营。

4、固废产业链化

扬子江药业集团全面梳理固体废物现状,充分挖掘固体废物资源化利用潜力,积极与固废处置单位建立合作关系,逐步提高固体废物综合利用率。如:集团联合活性炭生产单位,共同探索资源化利用路径,将原焚烧处置的废活性炭转化为回收利用,2024年回收利用废活性炭53吨;工厂委托有资质单位对污水站产生的污泥进行危险特性鉴别,鉴别结果为一般工业固废,通过生态环境部门备案后,与处置单位合作,利用干化技术,将污泥作为制砖原料,2024年综合利用污泥87.1吨。

Project Highlights

项目亮点

Based on the

current situation of solid waste at each factory, Yangtze River Pharmaceutical

Group has actively explored the paths of reducing, recycling and harmless

treatment of solid waste, aiming to minimize the environmental impact of the

solid waste generated by the company's production and operation activities

through the construction of an "environmentally Zero-Waste Group". As

of the end of August 2025, four of the group's factories have received the

local "zero-waste factory" honor.

扬子江药业集团基于各工厂固体废物现状,主动开展固体废物减量化、资源化和无害化路径探索,旨在通过“无废集团”建设,将企业生产经营活动产生的固体废物对环境的影响降至最低。截至2025年8月底,扬子江药业集团旗下4家工厂获得属地“无废工厂”荣誉。

Project Implementation

项目实施

"The

Waste-Free Group" is an expansion and extension of the national initiative

for "waste-free cities". In response to the call for building a

"waste-free group", and to promote the reduction of solid waste at

the source and its resource utilization by Yangtze River Pharmaceutical Group,

as well as to strengthen the management of solid waste throughout its

lifecycle, in October 2023, Yangtze River Pharmaceutical Group initiated the

construction of the first "waste-free group" in the Jiangsu

pharmaceutical industry. The group is committed to establishing a

"waste-free group" construction system with reduction and resource

utilization as the core, supported by information technology, and guaranteed by

institutional construction, with the aim of building a distinctive

"waste-free group" system of Yangtze River Pharmaceutical. Gradually,

a new model of "waste-free Yangtze River" has been established, promoting

the green and low-carbon development of the group and leading the new trend of

green development in the industry.

I. Construction

Scope

The construction of

the "waste-free group" involves 9 factories within Jiangsu Province,

jointly promoting the construction of the "waste-free group".

II. Construction

Goals

1. By the end of

2025, the intensity of industrial solid waste generation will be reduced to

0.048 tons per 10,000 yuan.

2. After 2025, the

construction of the "waste-free group" will be continuously advanced,

and the intensity of industrial solid waste generation will continue to be

reduced.

III. Key Measures

Taken

In 2024, Yangtze

River Pharmaceutical Group comprehensively reviewed the current situation of

solid waste management and identified projects for solid waste reduction,

resource utilization, and harmless treatment. In April 2024, the "Yangtze

River Pharmaceutical Group Construction Plan for a Waste-Free Group

(2024-2025)" (hereinafter referred to as the "Plan") was

compiled and passed the provincial expert review on solid waste management, and

received the approval document from the environmental protection department in

October 2024. The main measures of the Plan are as follows:

1. In terms of

solid waste reduction and resource utilization, through measures such as

reducing packaging waste, recycling organic solvents, promoting paperless

office operations, and Solid Waste Industrial Chain Integration, the intensity

of industrial solid waste generated by the group has been continuously reduced,

contributing to the achievement of the "zero waste" goal.

2. In terms of

solid waste management, the group's requirements for hierarchical and

classification management of hazardous waste and laboratory hazardous waste

management have been clarified, and these requirements have been integrated

into the "Regulations for the Prevention and Control of Solid Waste

Pollution Environment" and implemented throughout the group, promoting the

refined management of hazardous waste.

3. In terms of

information technology construction, with Yangtze River Pharmaceutical Group

Co., Ltd. as a pilot, a smart management platform for hazardous waste was

built. Through information technology means, the entire process of hazardous

waste management will be strengthened.

IV. Construction

Achievements

By the end of 2024,

the coverage rate of clean production audits for operating factories reached

100%, the reduction and utilization of industrial solid waste was approximately

1,929 tons, generating economic benefits of approximately 11.9 million yuan,

and the intensity of industrial solid waste generation was reduced to 0.0478

tons per 10,000 yuan, achieving the overall project goals ahead of schedule.

In the future,

Yangtze River Pharmaceutical Group will continue to explore measures for solid

waste resource utilization and reduction, strengthen the management of solid

waste throughout its lifecycle, promote the development of solid waste disposal

towards efficiency, intelligence, and low-carbonization, and contribute to the sustainable

development of the group.

“无废集团”是国家布局“无废城市”的拓展和延伸,为积极响应“无废集团”建设号召,推动扬子江药业集团固体废物源头减量与资源化利用,强化固体废物全过程管理,2023年10月,扬子江药业集团启动江苏省医药行业首家“无废集团”建设,致力于构建以减量化和资源化为核心、以信息化技术为支撑、以制度建设为保障的具有扬子江药业特色的“无废集团”建设体系,逐步建立起“无废扬子江”的崭新模式,推动集团实现绿色低碳发展。

一、建设范围:

“无废集团”建设工作涉及江苏省内9家工厂,共同推进“无废集团”建设。

二、建设目标:

1、到2025年底,工业固体废物产生强度降低至0.048吨/万元。

2、2025年后,持续推进“无废集团”建设工作,持续降低工业固体废物产生强度。

三、采取的关键措施

2024年扬子江药业集团全面梳理固体废物管理现状,挖掘固体废物减量化、资源化、无害化项目,2024年4月完成《扬子江药业集团“无废集团”建设实施方案(2024-2025)》(以下简称《方案》)编制并通过固体废物管理省级专家评审,2024年10月获得生态环境部门批复文件。《方案》主要举措如下:

1、在固体废物减量化与资源化方面,通过包材减量化、有机溶剂循环化、办公无纸化、固废产业链化等举措,持续降低集团工业固体废物产生强度,助力“无废”目标的达成。

2、在固体废物管理方面,明确了集团危险废物分级分类管理要求和实验室危险废物管理要求,并融入《固体废物污染环境防治管理规程》推行至全集团,促进危险废物的精细化管理。

3、在信息化建设方面,以扬子江药业集团有限公司为试点,建设危险废物智慧化管理平台,通过信息化手段加强危险废物全过程管理。

四、建设成果

截至2024年底,在产工厂清洁生产审核覆盖率100%,工业固体废物减量化、资源化约1929吨,产生经济效益约1190万元,工业固体废物产生强度降至0.0478吨/万元,提前达成项目整体目标。

未来,扬子江药业集团将持续挖掘固体废物资源化、减量化措施,强化固体废物全流程管理,推动固体废物处置向高效化、智能化、低碳化发展,助力集团可持续发展。

Project Impact & Sustainability

项目影响力、可推广性与可持续性

The

"zero-waste" construction of Yangtze River Pharmaceutical Group is an

expansion and extension of the national plan for "zero-waste cities".

Its aim is to reduce the generation intensity or total amount of solid waste in

the enterprise through measures such as solid waste reduction, resource

utilization, and harmless treatment, thereby minimizing the impact on the

environment. In 2025, the group innovatively proposed to carry out the

construction of "zero-waste workshops" within the factory. It

assesses each workshop based on the recovery rate of hazardous waste

generation, further implementing and refining the "zero-waste group"

construction work. At the same time, the group actively promotes the excellent

case experiences of "Zero-Waste Group": on the one hand, it

participated in the compilation of T/UNP 724—2025 "Guidelines for Zero-Waste Factory

Construction in Pharmaceutical Enterprises", leading the top-level design

of "zero-waste factories" in the pharmaceutical industry; on the

other hand, it leverages platforms such as "2025 International Forum on

Ecological Civilization in Guiyang ESG Cases" and "Outstanding ESG

Practices of Chinese Enterprises Internationalization" to share excellent

practices and assist the pharmaceutical industry in its "zero-waste"

transformation.

扬子江药业集团“无废集团”建设是国家布局“无废城市”的拓展和延伸,旨在通过固体废物减量化、资源化和无害化的举措,减少企业固体废物的产生强度或总量,从而降低对生态环境的影响。2025年,集团创新性地提出开展工厂内部“无废车间”建设,根据各车间危险废物产生回收利用率进行评比,进一步把“无废集团”建设工作落到实处、细处。与此同时,集团积极推广“无废集团”优秀案例经验:一方面参编T/UNP 724—2025《制药企业无废工厂建设指南》,引领医药行业“无废工厂”顶层设计;另一方面依托“2025生态文明贵阳国际论坛ESG案例”与“中国企业国际化ESG优秀实践”等平台,分享优秀做法,助力医药行业“无废化”转型。

(Using AI translation)

(使用AI翻译)

南平零废弃建设等案例,在联合国COP30大会上向全球发布!

12-04 · 来源:福建南平环境 · 作者:福建南平环境

上海市第六人民医院入选《2025美丽中国 · 绿色空间使用者典型案例集》

12-04 · 来源:徐汇生态环境 · 作者:徐汇生态环境

当青年演员/联合国新闻特派员走进COP30🌍

11-27 · 来源:DGUS · 作者:DGUS