Project Overview

案例概述

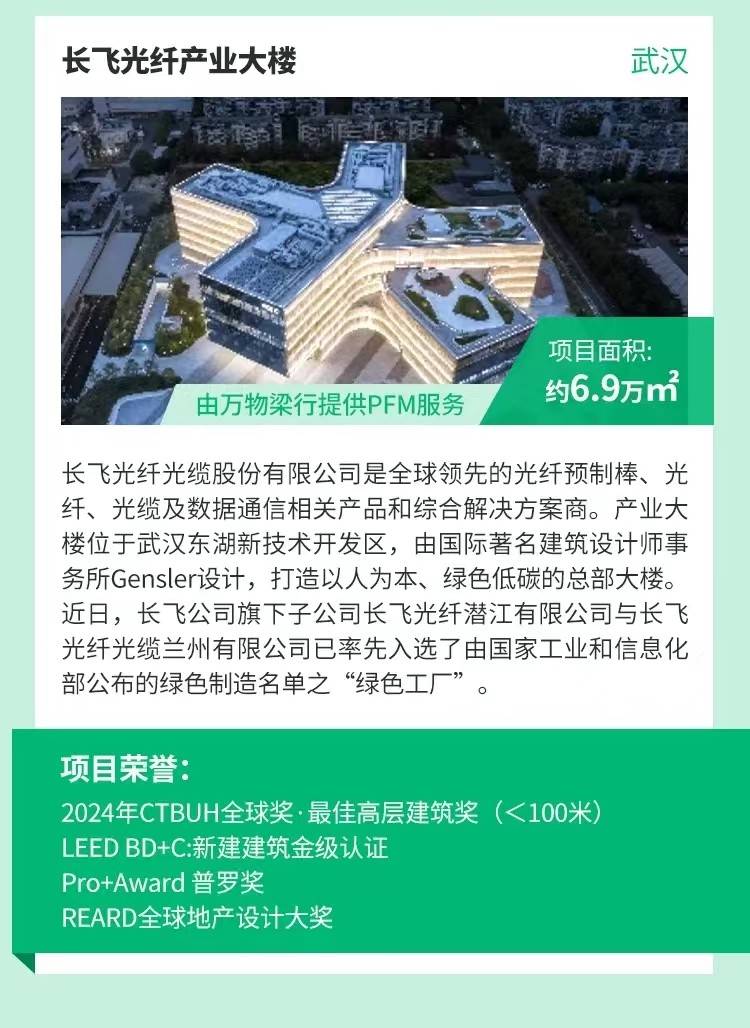

As a global leader in optical fiber technology, YOFC integrates

sustainable development principles into the entire process of building

construction and operational management. Its building, designed by Gensler and

awarded LEED Gold certification, incorporates green features such as a

"breathing" intelligent curtain wall and a rainwater recycling

system. Under the professional operation of the Cushman & Wakefield Vanke

Service property team since April 2023, it has achieved a systematic transition

from green construction to sustainable daily practices.

In terms of energy conservation, the building’s electricity

consumption in 2024 decreased by 444,100 kWh year-on-year. This was made

possible by a scientific energy management system that includes real-time load-based

adjustment of air conditioning, on-demand lighting, and "tidal

strategy" lighting control in the parking garage, significantly improving

energy efficiency.

For waste management, the property team promotes a

"zero-waste office" initiative through source reduction, accurate

classification, recycling alternatives, and employee engagement. In the first

month of the pilot, over 67 tons of plastic, paper, food waste, and other

recyclables were collected. The team also organizes low-carbon campaigns and produced

an in-house video titled "A Day of Zero Waste," using engaging

methods to raise environmental awareness among employees.

With technology-driven energy savings and a culture of

sustainability, YOFC has established an efficient operational system that

integrates safety, green principles, and human-centric synergy, serving as an

exemplary benchmark of full-lifecycle low-carbon practice in the industry.

作为全球光纤技术领域领先企业,长飞光纤将可持续发展理念全面融入建筑与运营全过程。大楼由 Gensler 设计,获 LEED 金级认证,以 “会呼吸” 的智能幕墙、雨水回收系统等绿色设计为基础,2023 年 4 月起万物梁行物业团队的专业运营下,实现了从绿色建造到绿色运行的系统性低碳实践。

在节能方面,2024 年大楼总用电量同比降低 44.41 万度,主要依托科学的能源管理体系:包括空调负荷实时调控、照明系统 “按需供光”、车库 “潮汐式” 照明控制等多项技术措施,显著提升能源使用效率。

在废弃物管理方面,物业团队推动 “零废弃办公”,通过源头减量、精准分类、资源循环和意识提升,试点首月累计回收塑料、废纸、厨余等各类垃圾超过 67 吨。物业团队每年组织开展地球日、熄灯日等各类低碳宣传活動,自制《“零废弃” 的一天》视频,以轻松有趣的方式深化员工低碳意识。

长飞光纤不仅以技术节能,更以文化赋能,构建了安全、绿色、人文协同的高效运营体系,成为具有行业借鉴意义的全周期低碳实践标杆。

Company/Organization Profile

机构简介

Established in May 1988, Yangtze Optical Fibre and Cable (YOFC)

stands as one of China's earliest manufacturers of optical fibers and cables.

The company was initially founded as a tripartite joint venture among the

former Ministry of Posts and Telecommunications, the Wuhan Municipal

Government, and Philips of the Netherlands. Its name "长飞" (Changfei) derives from the phrase "长江边的飞利浦" (Philips by the Yangtze River), reflecting its origins.

The company integrates R&D and production of core products

including preforms, optical fibers, and optical cables, holding a leading

global market share for consecutive years. Its products, known for ultra-low

attenuation and superior bend resistance, are industry-leading. YOFC is a core

supplier for national strategic projects such as 5G, marine communications, and

ultra-high voltage (UHV) transmission, with a dominant share in the high-end

market.

长飞公司成立于 1988 年 5 月,是国内最早的光纤光缆生产商之一,是全球光纤光缆行业领军者,集核心预制棒、光纤及光缆研发生产于一体,连续多年稳居全球市场份额第一。最初由原邮电部、武汉市政府和荷兰飞利浦公司三方合资成立,被称为长江边的飞利浦,“长飞” 由此而来。公司在国内长三角、珠三角及海外印尼、南非等地建有多个生产与销售公司,形成辐射全球的研产销网络。产品以超低衰减、超强抗弯性引领行业,是 5G、海洋通信、特高压等国家战略项目的核心供应商,高端市场份额绝对领先。

Project Outcome

项目成果

Through a combination of technical and managerial measures by

the property management team, energy efficiency has significantly improved:

total electricity consumption in 2024 decreased by 444,100 kWh compared to

2023, while over 700 tons of waste was sorted and recycled.

Integrated energy-saving technical measures were systematically

implemented. The building's triple-layer "breathing" facade optimizes

indoor light and heat, reducing HVAC load from the source. The HVAC system's

efficiency was enhanced through:

1. Dynamic Load Management: Saving 650 kWh per hour by shutting

down redundant units when load is below 60%.

2. Zoned Controls: Saving approximately 2700 kWh per weekend day

by powering down high-use zones after hours.

3. Smart Lighting: Office lighting auto-adjusts to maintain

300–400 Lux, while garage "tidal lighting" reduces brightness from

50% to 25% during off-peak hours, ensuring safety without waste.

Operational and cultural initiatives drove sustainable

practices. A “Zero-Waste Office” initiative, emphasizing source reduction and

sorting, successfully recovered over 67 tons of recyclables in its first month.

This was supported by robust low-carbon promotion and staff engagement, with

annual participation reaching over 5,000 person-times. Activities included

Earth Day events, a self-produced A Day of Zero Waste video, and green

commuting challenges, successfully fostering a company-wide culture of

sustainability.

减排量、节能量/率、科普/动员参与活动的人数,污染物减少量,废弃物减少量,其他环境/社会/经济效益(如对自然环境和生活环境的改善以及成本减少和收益增加等),内容不超过5条。在物业团队多项技术与管理措施的综合作用下,能效提升成果显著:2024年总用电量较2023年大幅减少44.41万度;垃圾分类回收超700吨。

1. 智能幕墙系统:建筑外立面采用三层智能幕墙,可根据日照强度自动调节百叶角度,犹如 “呼吸系统”,有效调控室内光热环境,从源头降低空调负荷。

2. 空调系统优化:动态负载管理: 实时监测主机负载,在负载低于 60% 时自动关闭冗余主机及配套设备,每小时可节电 650kWh。分时分区控制: 依据空间使用特性划分高低区,工作日 19:00 后及周末关闭高区空调,仅周末单日即可节电约 2700kWh。无人区温控策略: 将无人区域空调温度统一上调至 28℃,并降低风柜运行频率,平衡能耗。

3. 智慧照明改造:办公区: 采用智能照明系统(BA 智控),根据室外光照度自动调节室内灯具,维持恒定的 300-400Lux 照度;人员离开 20 分钟后自动熄灯。车库: 实施 “潮汐式” 照明策略,高峰期全亮,非高峰时段及夜间将车道照明亮度从 50% 降至 25%,在确保安全的前提下杜绝无效照明。无人区: 非办公时间仅保留巡更所需的走廊及卫生间基础照明。

4. 垃圾分类:在废弃物管理方面,物业团队推动 “零废弃办公” 试点,通过源头减量、精准分类、资源循环和意识提升,试点第一个月累计回收塑料、废纸、厨余等各类垃圾超过 67 吨。

5. 低碳宣传与员工参与:团队还组织低碳宣传活动,如每年世界地球日开展垃圾分类游戏、低碳环保知识问答、以书换 “蔬” 公益活动;在 “地球熄灯日” 开展熄灯节能公益活动;自制《“零废弃”

的一天》视频,以轻松有趣的方式倡导低碳办公生活;举办绿色出行、二手市集交换公益活动等;低碳节能宣传贯穿全年,年参与人次达 5000 余人。

在物业团队多项技术与管理措施的综合作用下,能效提升成果显著:2024 年总用电量较 2023 年大幅减少 44.41 万度;垃圾分类回收超 700 吨。

Project Highlights

项目亮点

The project consistently prioritizes the use of existing

building spaces and equipment systems, enhancing performance through smart

retrofits rather than extensive demolition and reconstruction. In terms of

ecological synergy, it innovatively integrates an energy management platform

with property operational processes, enabling cross-system low-carbon

coordination. The project has been awarded LEED Gold certification and several

international accolades. Users widely report a significant improvement in

environmental comfort, while the property team highlights the system’s

user-friendliness and strong sustainability, demonstrating outstanding

multi-stakeholder synergy.

本项目始终坚持优先利用既有建筑空间与设备系统,通过智能化改造实现效能提升,避免大拆大建。在生态协同方面,创新整合能源管理平台与物业运营流程,实现跨系统低碳联动。项目获 LEED 金级认证及各位国际奖项。用户普遍评价环境舒适度显著提升,物业团队反馈系统操作便捷、可持续性强,多方协同效果突出。

Project Implementation

项目实施

In advancing the 'Zero-Waste Office' initiative, the team faced

multiple challenges such as changing habits and system conversion. However,

through effective strategies and support from all parties, they successfully

overcame these difficulties and achieved remarkable results.

Employees found it difficult to break old habits and showed low

compliance in the initial stage: despite the installation of separate waste

bins, they still tended to discard all trash into their personal desktop bins,

rendering precise waste sorting in pantry areas ineffective. Moreover, policies

such as not providing disposable cups caused inconvenience and led to

resistance.

After thorough discussions, the project team adopted a combined

approach of continuous awareness guidance and economic incentives. On one hand,

they repeatedly promoted waste sorting knowledge and the environmental

significance of the project through internal emails, promotional posters,

kick-off meetings, and other forms of communication. On the other hand,

tangible incentives such as "bring-your-own-cup discounts" at the

coffee bar were introduced to motivate employees to shift from "passive

compliance" to "active participation," gradually fostering new

habits.

The success of the project relied on the collaboration and

resource investment from multiple parties both inside and outside the company.

The leadership at Yangtze Optical Fibre and Cable Joint Stock Limited Company

(YOFC) provided special authorization and financial support, which served as

the cornerstone of the project by approving the purchase of sorting bins, the

renovation of waste disposal rooms, and subsidies for "Bring Your Own

Cup" incentives.

The property management team, serving as the core implementing

body, demonstrated full cohesion and collaboration. They were responsible for

the daily maintenance of facilities, the redesign and execution of cleaning

procedures, secondary sorting of waste (particularly crucial in the initial

stages), and preliminary data collection (such as waste weighing). Their work

was fundamental to the successful implementation of the project.

All departments participated simultaneously and assisted in

promotion. HR, Administration, Finance, and other teams provided substantial

support in areas such as promotional campaigns, process transformation, and

employee guidance, working together to integrate the new initiatives into the

company culture.

在推进 “零废弃办公” 过程中,团队面对习惯改变、系统转换等多重挑战,但通过有效的策略和各方支持,成功克服困难,取得了显著的成效。

员工旧习惯难以改变,初期配合度低:尽管设置了分类垃圾桶,但员工仍习惯将所有垃圾丢入个人桌面桶,导致茶水间的精准分类形同虚设;对于不提供一次性水杯等规定感到不便,存在抵触情绪。

项目团队经过重重探讨,通过持续的意识引导和经济杠杆相结合。一方面,通过内部邮件、宣传海报、启动会等形式反复宣导垃圾分类知识和项目环保意义;另一方面,通过咖啡吧 “自带杯优惠” 等实实在在的激励,让员工从 “被动要求” 转变为 “主动参与”,逐步培养新习惯。

项目的成功离不开公司内外的多方协力与资源投入,长飞总部领导对此给予专项授权和资金支持。批准采购分类垃圾桶、改造垃圾房、设置 “自带杯优惠” 补贴等,是项目启动的基石。

物业团队作为核心执行方,全体人员凝心聚力、通力协作,他们负责设施的日常维护、清洁流程的重新制定与执行、垃圾分类的二次分拣(在初期尤为重要)以及数据的初步统计(如垃圾称重),他们的工作是项目落地的保障。

各部门同步参与并协助推广,HR、行政、财务等部门在宣传推广、流程变革、员工引导方面给予了巨大支持,共同推动新规成为公司文化的一部分。

Project Impact & Sustainability

项目影响力、可推广性与可持续性

To actively respond to the national call for energy conservation

and emission reduction, the YOFC industrial building actively explores the

application of low-cost, high-flexibility IoT energy-saving technologies in its

green operations, effectively enhancing the precision management of

electricity-consuming equipment.

We have taken the lead in introducing IoT-based control systems

in certain areas, gradually phasing out traditional single-timer devices. This

system supports real-time monitoring and adjustment of electricity-consuming

devices via mobile terminals, offering not only low investment costs but also

significantly enhancing control convenience and response speed, effectively

eliminating wasteful energy consumption.

Meanwhile, we have equipped split air conditioners in computer

rooms with infrared temperature-sensing switches, enabling automatic on/off

operation within set temperature ranges (e.g., turning on at 26°C and off at

24°C). This achieves unmanned intelligent temperature control, significantly

reducing unnecessary runtime of air conditioners and lowering additional energy

consumption.

These two technologies require small investments, deliver quick

results, and are easy to replicate. They not only provide new pathways for low-carbon

building operations but also serve as valuable models for energy-saving

renovations in small and medium-sized computer rooms and office areas. In the

future, we plan to extend the application of IoT-based electricity control and

infrared temperature-sensing technologies to more scenarios, and explore

further integration with building automation systems to continuously tap into

energy-saving potential and support the green transformation of the industry.

为积极响应国家节能减排号召,长飞光纤产业大楼在绿色运营中积极探索低成本、高灵活度的物联网节能技术应用,有效提升了用电设备的精细化管理水平。

我们率先在部分区域引入物联网控制系统,逐步替代传统单一时控器。该系统支持远程手机端实时监控和调节用电设备,不仅投入成本低,更大幅提升了调控便利性与响应速度,有效杜绝无效能耗。

同时,我们为机房分体空调加装了红外感温开关控制器,设定温度区间自动启停(如 26℃启动,24℃关闭),实现无人化智能温控,显著减少空调非必要运行时间,降低额外能耗。

这两项技术投入小、见效快、易复制,不仅为楼宇低碳运营提供了新路径,也对中小型机房和办公区节能改造具有良好的示范意义。未来,我们计划将物联网控电与红外感温技术扩展至更多应用场景,并探索与楼宇自控系统进一步融合,持续挖掘节能潜力,助力行业绿色转型。

(Using AI translation)

(使用AI翻译)

南平零废弃建设等案例,在联合国COP30大会上向全球发布!

12-04 · 来源:福建南平环境 · 作者:福建南平环境

上海市第六人民医院入选《2025美丽中国 · 绿色空间使用者典型案例集》

12-04 · 来源:徐汇生态环境 · 作者:徐汇生态环境

当青年演员/联合国新闻特派员走进COP30🌍

11-27 · 来源:DGUS · 作者:DGUS